T: +86-189-2891-8174

E: wechupack@yeah.net

E: wechupack@yeah.net

104 The Second Building, No.43 Haichong Road, Shiqi Town,Panyu District, Guangzhou City, China

Views: 0 Author: Site Editor Publish Time: 2025-06-16 Origin: Site

A sauce packaging machine is an automated system that fills, seals, caps, and labels containers with sauce products. It’s essential in the food industry for businesses making ketchup, hot sauce, BBQ sauce, and more. This machine improves efficiency, keeps sauces safe from contamination, and ensures every container has the same amount of product.

Manufacturers use sauce filling machines, sauce capping machines, and sealing systems to meet high-volume demands. These machines make sure every container is sealed tight, labeled correctly, and packaged safely. This guide explains how they work, what types exist, and how to choose the best one for your needs.

The demand for sauces grows every year. Shoppers want convenience and variety. A good sauce packaging machine keeps your product looking clean and professional. It helps extend shelf life, prevents leaks, and builds customer trust.

By reducing manual labor, these machines lower operating costs. They also boost output. In competitive markets, that’s a big win.

Related Keywords: sauce filling machine, sauce capping machine, sauce sealing machine, sauce labeling machine, sauce packaging equipment

Different sauces need different machines. Thick sauces, like mayo or salsa, require machines with piston pumps. Thin sauces, like soy or vinegar, flow better and use other systems. Let’s look at the most common machine types.

Sauce filling machines inject sauce into containers. There are three main types:

| Type | Best For | Features |

|---|---|---|

| Piston Fillers | Thick sauces | High accuracy, good for viscous liquids |

| Volumetric Fillers | Medium-thin sauces | Consistent fill volume, adjustable output |

| Flow Fillers | Thin sauces | Fast fill rates, less spillage risk |

These machines handle bottles, jars, and pouches. Many models include anti-drip features. They keep machines clean and reduce waste.

Sauce capping machines secure lids or caps. Without them, sauces would spill or spoil. There are three main capping systems:

| Machine Type | Cap Type | Advantages |

|---|---|---|

| Screw Capper | Twist caps | Fast and consistent |

| Snap Capper | Push-on lids | Great for plastic tubs and bottles |

| Chuck Capper | Press & twist | Secure grip, handles various shapes |

These machines ensure your containers are sealed tight. This extends freshness and keeps out air and bacteria.

After capping, some containers need an extra seal. This adds a safety layer. Sauce sealing machines work with jars, pouches, or tubs. Common options:

Jar sealing machines: Apply heat seals or shrink bands

Vacuum sealing machines: Remove air, great for high-end sauces

Pouch sealers: Ideal for small packets or bulk sauce bags

Sealing improves shelf life. It also adds tamper evidence for safety.

Labels tell customers what’s inside. Sauce labeling machines apply labels automatically. They work on jars, pouches, and bottles. You can print product info, branding, and logos.

Coding machines print expiration dates and batch numbers. This ensures traceability. It’s required for compliance in most countries.

There are two types:

Automatic labelers: High speed, good for big operations

Semi-automatic labelers: Budget-friendly, great for small batches

You can combine all machines into a full sauce packaging line. These lines handle everything from filling to labeling. Advantages:

Higher speed

Less labor

Reduced contamination risk

Integrated systems are scalable. You can start small and upgrade later.

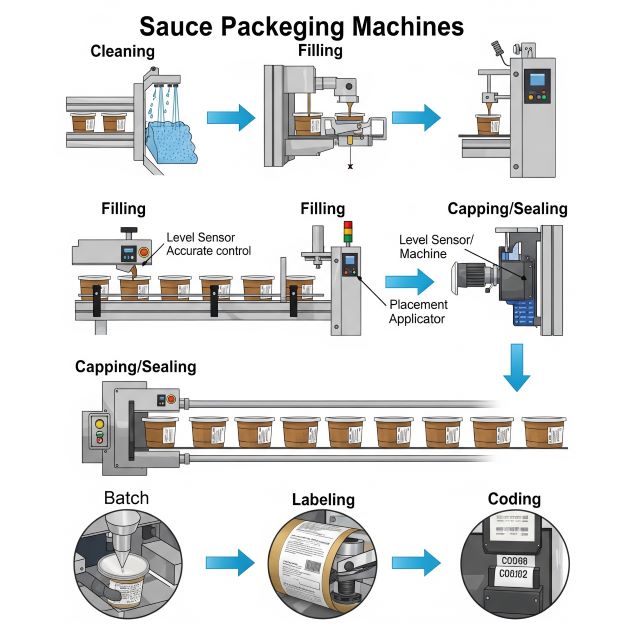

Let’s look at how the full process works step by step:

Cleaning: Bottles and jars enter a rinsing station to remove dust

Filling: A sauce filling machine dispenses the correct amount of sauce

Capping/Sealing: Lids are applied, and jars may be sealed with heat

Labeling: Brand labels are applied automatically

Coding: Batch numbers and expiry dates are printed

All these steps can happen on one continuous line. Sensors ensure containers are aligned and filled correctly. Most systems are programmable. This means you can set fill levels or label positions easily.

When machines are linked, they work faster. Operators don’t need to touch the product. You get:

Cleaner production

Fewer errors

Better traceability

Consistent quality

Modern machines include touchscreen interfaces. Some offer remote monitoring via the cloud.

Not every machine fits every operation. Here’s what to consider.

Your container matters. Different machines handle:

| Container Type | Best Machine Match |

|---|---|

| Glass jars | Piston filler, screw/chuck capper |

| Plastic bottles | Flow filler, snap capper |

| Stand-up pouches | Volumetric filler, pouch sealer |

Make sure your packaging line supports your container shape and size.

Estimate how many units you need per hour. Small businesses may only need 500. Large factories need 10,000+.

| Machine Type | Speed Range | Best For |

|---|---|---|

| Manual | < 500 units/hour | Startups, test runs |

| Semi-Automatic | 500–2000 units/hour | Small to medium producers |

| Fully Automatic | 2000–10,000+ units/hour | Large-scale manufacturers |

Choose based on your target production level.

Accurate filling ensures every bottle has the right amount. This builds trust and cuts waste. Look for:

Servo-driven pistons

Anti-drip nozzles

Real-time sensors

Machines run daily. Look for strong frames, stainless steel parts, and easy-clean designs. Features to prioritize:

Tool-free adjustments

Easy-to-replace nozzles or belts

Built-in diagnostics

Choose a supplier that offers after-sales service and spare parts.

Fully automatic machines cost more but save labor. Manual or semi-automatic machines are cheaper and flexible.

Ask:

Will production grow?

Do we need less downtime?

Are workers trained to operate automated systems?

Automation improves output and consistency. It pays off in the long term.

Machines fill, cap, and label faster than humans. They reduce human fatigue and error.

Every bottle or jar looks the same. The sauce amount is exact. Labels don’t wrinkle. Capping is uniform. This builds brand trust.

You save on labor. You reduce wasted sauce. You avoid customer complaints from underfilled bottles. All this improves profit margins.

Sealed jars last longer. Vacuum-packed sauces stay fresh. Contamination is reduced.

Your packaging looks professional. Labels help with brand recognition. Expiry dates keep you compliant.

TENGZHUO makes reliable and customizable sauce packaging machines. Their product line includes:

Piston filling machines for thick sauces

Capping and sealing machines

Complete packaging lines

Advantages:

Compact designs

User-friendly interfaces

Support for glass jars, PET bottles, and pouches

TENGZHUO offers global shipping and responsive customer service.

Clean nozzles daily

Inspect belts and seals weekly

Replace worn parts immediately

Use food-safe lubricants. Keep a log for every machine.

| Issue | Cause | Solution |

|---|---|---|

| Inconsistent filling | Air bubbles, worn pistons | Recalibrate or replace pistons |

| Leaky seals | Low heat, misaligned sealers | Adjust sealing temperature or align |

| Label misplacement | Worn rollers, misfeeds | Clean rollers, check label feed |

A sauce packaging machine boosts production speed, product quality, and consistency. It reduces errors, enhances shelf life, and improves branding. From sauce filling machines to labeling and capping systems, every part plays a vital role.

Evaluate your container type, production needs, and automation level. Choose a reliable supplier. Maintain your equipment regularly. These steps ensure a profitable and smooth production line.

Interested in scaling your sauce business? Contact TENGZHUO or a trusted supplier for a tailored solution.

What is the best sauce packaging machine for small businesses?

Semi-automatic piston fillers paired with manual cappers. They’re cost-effective and flexible.

How do I choose the right sauce filling machine?

Consider sauce viscosity, container type, and output speed. Piston fillers work best for thick sauces.

Can sauce packaging machines be customized for different sauce types?

Yes. Many suppliers offer machines with adjustable settings for different viscosities and volumes.

What are the common issues with sauce packaging machines and how can they be fixed?

Common issues include leaks, misfills, and labeling errors. Regular maintenance and timely part replacements solve most problems.

The Ultimate Guide To Filling Machines for Cosmetics

The Ultimate Guide To Pouch Packing Machines:Types,Benefits,And Buying Tips

Types of Sealing Machines: 13 types of Packaging Solutions Sealing Machines

The Ultimate Guide To Choosing The Right Coffee Packaging Machine