T: +86-189-2891-8174

E: wechupack@yeah.net

E: wechupack@yeah.net

104 The Second Building, No.43 Haichong Road, Shiqi Town,Panyu District, Guangzhou City, China

Views: 0 Author: Site Editor Publish Time: 2025-06-09 Origin: Site

A coffee packaging machine isn’t just a tool—it’s a game-changer. It protects flavor, locks in freshness, and keeps coffee beans safe from air, light, moisture. If you're serious about quality, you need the right machine.

Why does it matter so much? Once roasted, coffee starts to degrade. Poor packaging speeds that up. The right machine keeps your coffee shop or roasting business consistent and trusted. Good packaging also boosts brand perception. Customers associate great packaging with premium quality. It becomes part of the brand story.

There are three main types: manual, semi-automatic, and fully automatic. Each serves different scales and budgets.

A coffee packaging machine is a system designed to fill, seal, and sometimes label coffee bags. It automates parts of the packaging process, making things faster and more consistent.

Core components:

Filling system: Measures and dispenses the right amount of coffee.

Sealing mechanism: Applies heat and pressure to close the bag.

Gas flushing (optional): Replaces oxygen with nitrogen to extend shelf life.

Production workflow: After roasting and cooling, coffee is weighed and packed. The machine ensures every pack looks uniform and stays fresh.

Manual sealers use heat to close bags. They include hand sealers and foot-operated sealers. These are perfect for small roasters or artisan brands producing fewer than 30 bags per hour.

Pros:

Low cost

Easy to learn

Suitable for short production runs

Cons:

Labor-intensive

Limited output capacity

Ideal for medium-scale roasters. These machines handle filling and sealing but may need human input for positioning bags or labels. They improve speed and reduce inconsistencies.

When to switch: When daily output exceeds 50-100 bags. Manual methods become inefficient and error-prone.

These systems do it all: weigh, fill, seal, print dates, and label. They work continuously and deliver output of 30+ packs per minute. Perfect for commercial roasters.

Pros:

High-speed production

Minimal labor required

Consistent results

Cons:

High upfront investment

More maintenance needed

Some machines offer unique features:

Vacuum packaging: Removes oxygen before sealing to prevent oxidation

Nitrogen flush systems: Adds nitrogen gas to preserve aroma

Pod packaging systems: Tailored for capsules or coffee pods

Different machines handle different bag styles. Common options include:

| Bag Type | Features | Common Use |

|---|---|---|

| Stand-up Pouch | Resealable, good for shelf display | Retail packaging |

| Quad-Seal Bag | Reinforced corners, premium look | High-end specialty coffee |

| Flat Bottom Bag | Five printable panels, stands well | Premium retail, gift sets |

| Gusseted Bag | Traditional, stores well | Bulk or wholesale packaging |

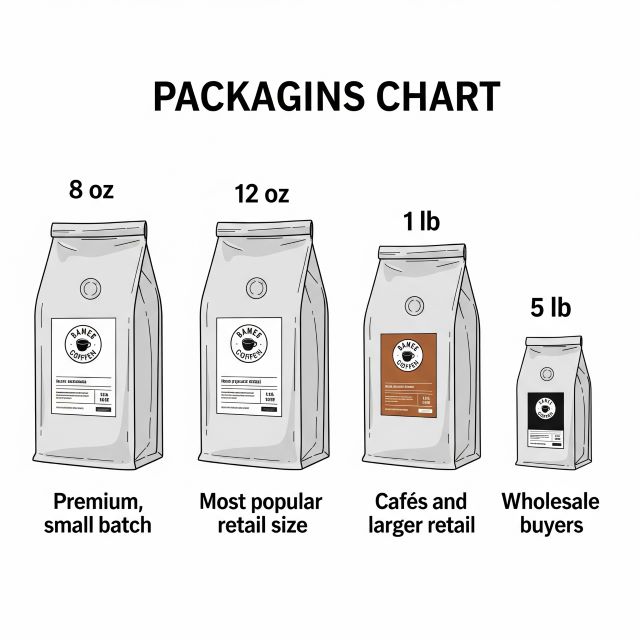

Your machine should support various bag sizes. Common capacities:

8 oz: Premium, small batch

12 oz: Most popular retail size

1 lb: Cafes and larger retail

5 lb: Wholesale buyers

Custom sizes: Single-serve or samples

Impulse sealers use energy only when sealing. Efficient, safe, ideal for thinner bags (up to 10mm).

Direct heat sealers stay hot continuously. Best for thick packaging (10mm+).

Choose based on packaging material and frequency.

Calculate how many bags/hour your operation needs. Here’s a rough breakdown:

| Machine Type | Output Rate (bags/hr) |

| Manual | 10–30 |

| Semi-Automatic | 50–200 |

| Fully Automatic | 300+ |

Match your sealer to your packaging material:

| Material | Recommended Sealer |

| Kraft Paper | Impulse or direct heat |

| LDPE | Impulse |

| PLA (eco) | Precision heat required |

Thicker, multilayer materials need more heat penetration. Precision is key.

Modern coffee packaging machines offer smart features:

Digital displays

Programmable settings

Auto error detection

Manual versions use levers or foot pedals. Automatic systems use sensors and touchscreen controls.

Green packaging is no longer optional. Consumers want biodegradable or recyclable bags.

Popular eco-materials:

Kraft paper

PLA linings

Recyclable LDPE

Make sure your machine supports sustainable packaging. Some machines can overheat or damage fragile materials.

Over 60% of customers are willing to pay more for eco-friendly packaging. Align your brand with that trend.

| Machine Type | Initial Cost | Labor Cost | Ideal For |

| Manual | Low ($100-$500) | High | Startups, artisan roasters |

| Semi-Automatic | Medium ($1k-$5k) | Medium | Growing roasters |

| Automatic | High ($10k+) | Low | Industrial scale |

Don’t forget installation, training, and maintenance.

Consider energy use. Impulse sealers save power. Direct heat sealers consume more but seal thicker bags.

Choose models with local support. This lowers downtime and ensures parts are easy to source.

Manual sealers are enough. Packaging is more about brand look and feel. Use natural materials and hand-crafted designs.

As orders increase, invest in semi-automatic systems. Look for models with better speed and optional nitrogen flushing.

Include resealable closures and degassing valves to enhance freshness.

Automate everything. Your machine should include auto-weighing, sealing, printing, and gas flushing.

Focus on speed and consistency. Choose a model that integrates with existing production lines.

Routine care extends lifespan. Here’s what to check:

Clean sealing bars daily

Check wiring or power lines weekly

Inspect heating elements monthly

Safety tips:

Always turn off after use

Use gloves when working with direct heat machines

Train staff on emergency procedures

Trusted brands offer better warranties, global service, and reliable parts. Some top names:

| Manufacturer | Notable Feature |

| Audion | Portable, high-quality manual |

| MTPak Coffee | Sustainable solutions |

| Roastar | Fully customizable designs |

| Savor Brands | Digital print specialists |

Compare suppliers based on:

MOQ (Minimum Order Quantity)

Lead times

Tech support availability

Global reach

Yes, as long as the filler is adjustable.

Typically 3–5 years with regular maintenance.

Recommended for premium coffee. Helps preserve aroma and shelf life.

Check thickness and melting point. Test a sample before mass production.

Choosing the right coffee packaging machine boosts quality, improves brand image, and supports business growth. Match your machine to your scale, goals, and materials.

Whether you're sealing 10 bags a day or 1,000 an hour, there's a machine for you. Test different options. Get supplier advice. Invest wisely.

Your coffee deserves packaging that protects and sells. With the right machine, it’s easy to deliver freshness, consistency, and style—every time.

The Ultimate Guide To Filling Machines for Cosmetics

The Ultimate Guide To Pouch Packing Machines:Types,Benefits,And Buying Tips

Types of Sealing Machines: 13 types of Packaging Solutions Sealing Machines