Uyini umshini wokufaka we-sauce?

Umshini wokupakisha we-Sauce uhlelo oluzenzakalelayo olugcwalisa, uphawu, izigqoko, kanye namalebula ezitsheni ngemikhiqizo ye-sauce. Kubalulekile embonini yokudla yamabhizinisi enza i-ketchup, isoso elishisayo, isoso le-BBQ, nokuningi. Lo mshini uthuthukisa ukusebenza kahle, ugcina amasoso aphephile ekungcolisweni, futhi aqinisekise ukuthi zonke izitsha zinenani lomkhiqizo elifanayo.

Abakhiqizi basebenzisa imishini yokugcwaliswa kweSauce , Souce caplines , nezinhlelo zokubopha uphawu lokuhlangabezana nezimfuno eziphezulu. Le mishini iqinisekisa ukuthi zonke izitsha zivaliwe ziqinile, zibhalwe kahle, futhi zipakishwe ngokuphephile. Lo mhlahlandlela uchaza ukuthi basebenza kanjani, yiziphi izinhlobo ezikhona, nokuthi ungazikhetha kanjani okungcono kakhulu ngezidingo zakho.

Kungani imishini yokupakisha ye-Sauce ibalulekile?

Isidingo sososo sikhula njalo ngonyaka. Abathengi bafuna lula nezinhlobonhlobo. omuhle Umshini wokufaka weSauce ugcina umkhiqizo wakho ubukeka uhlanzekile futhi uchwepheshe. Kuyasiza ukunweba impilo yeshede, kuvimbela ukuvuza, futhi kwakha ukwethenjwa kwamakhasimende.

Ngokunciphisa umsebenzi wezandla, le mishini ephansi izindleko zokusebenza. Ziphinde zikhulise okuphumayo. Ezimakethe zokuncintisana, lokho kuyimpumelelo enkulu.

Amagama agqamile : Umshini wokugcwalisa weSauce, umshini we-sauce cap page, umshini wokufaka uphawu weSauce, Umshini we-Sauce ilebula, Imishini yokupakisha yeSauce

Izinhlobo zemishini yokupakisha yeSauce

Amasoseji ahlukene adinga imishini ehlukile. Amasoso abukhulu, njenge-mayo noma i-salsa, adinga imishini enamaphampu wePiston. Amasoso amancanyana, afana no-soy noma uviniga, ageleze kangcono futhi asebenzise ezinye izinhlelo. Ake sibheke izinhlobo zomshini ezivame kakhulu.

Imishini yokugcwalisa yeSauce

Imishini yokugcwalisa yeSauce ifaka i-sauce ibe iziqukathi. Kunezinhlobo ezintathu eziphambili:

| thayipha |

kahle |

izici |

| Ama-piston fillers |

Amasoso abulili |

Ukunemba okuphezulu, okuhle koketshezi olubonakalayo |

| Ama-volumetric fillers |

Amasoso aphakathi nendawo |

Ivolumu yokugcwalisa engaguquki, ukuphuma okuguqukayo |

| Ama-Flow Fickers |

Amasoso amancanyana |

Amanani wokugcwalisa okusheshayo, ubungozi obuncane bokuchitheka |

Le mishini ibhekele amabhodlela, izimbiza kanye nezipuni. Amamodeli amaningi afaka izici ze-anti-drip. Bagcina imishini ihlanzekile futhi inciphisa imfucuza.

Imishini ye-Sauce cap ngemali

I-Sauce capping yemishini yamabholoji noma ama-cap. Ngaphandle kwabo, amasoso azochitha noma aphange. Kunezinhlelo ezintathu ze-capling ezinkulu:

| uhlobo lomshini |

we-cap cap hlobo |

izinzuzo |

| Screw capper |

Ukusonta caps |

Kushesha futhi kungaguquki |

| Snap capper |

Push-on amabhodlela |

Kuhle ngamashubhu epulasitiki namabhodlela |

| Chuck Capper |

Cindezela & Twist |

Ukubamba okuphephile, kuphatha amajamo ahlukahlukene |

Le mishini iqinisekisa ukuthi iziqukathi zakho zivaliwe ziqinile. Lokhu kunwebeka okusha futhi kugcina umoya namagciwane.

Imishini yokubopha uphawu leSauce

Ngemuva kokuphoqelelwa, ezinye iziqukathi zidinga uphawu olungeziwe. Lokhu kwengeza ungqimba lokuphepha. Imishini yokubopha uphawu leSauce isebenza nezimbiza, amaphakethe, noma amashubhu. Izinketho ezijwayelekile:

Imishini yokuvalwa kwe-jar : faka izimpawu zokushisa noma ama-shrink band

Imishini yokuvala uphawu kwe-Vacuum : Susa umoya, ulungele amasoso aphezulu wokuphela

I-Pouch Sealers : Ilungele amaphakethe amancane noma izikhwama ze-souce eningizimu

Ukuvalwa kwalonakalisa kuthuthukisa impilo yeshelufu. Iphinde yengeze ubufakazi obuphazamisayo bokuphepha.

I-Sauce ilebula nemishini yokufaka amakhodi

Amalebula atshela amakhasimende ukuthi yini ngaphakathi. Imishini ye-Sauce ifaka amalebula ngokuzenzakalelayo. Basebenza ezitsheni, ezipuni nasemabhodleleni. Ungaphrinta imininingwane yomkhiqizo, uphawu, nama-logo.

Imishini yokufaka amakhodi phrinta izinsuku zokuphelelwa isikhathi nezinombolo ze-batch. Lokhu kuqinisekisa ukulandelela. Kudingeka ukuhambisana namazwe amaningi.

Kunezinhlobo ezimbili:

Ama-Automageagers : Ijubane eliphakeme, lihle ngemisebenzi emikhulu

Ama-Refer-Automatic Managers : Ibhajethi-Inobungane, Ilungele Amabheji Amancane

Imigqa yokupakisha yeSauce

Ungahlanganisa yonke imishini emugqeni ogcwele wokupakisha we-Sauce . Le migqa ibhekele konke kusuka ekugcwalisweni kuya ekulebula. Izinzuzo:

Izinhlelo ezihlanganisiwe ziyakhubazeka. Ungaqala okuncane nokuthuthukile ngokuhamba kwesikhathi.

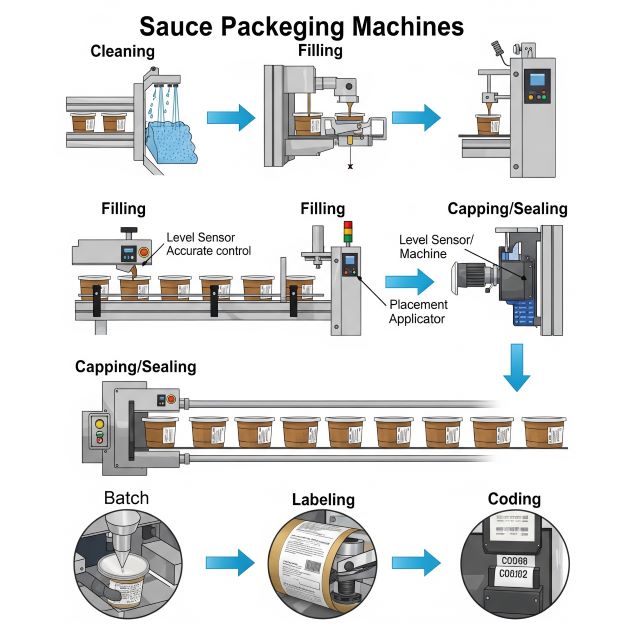

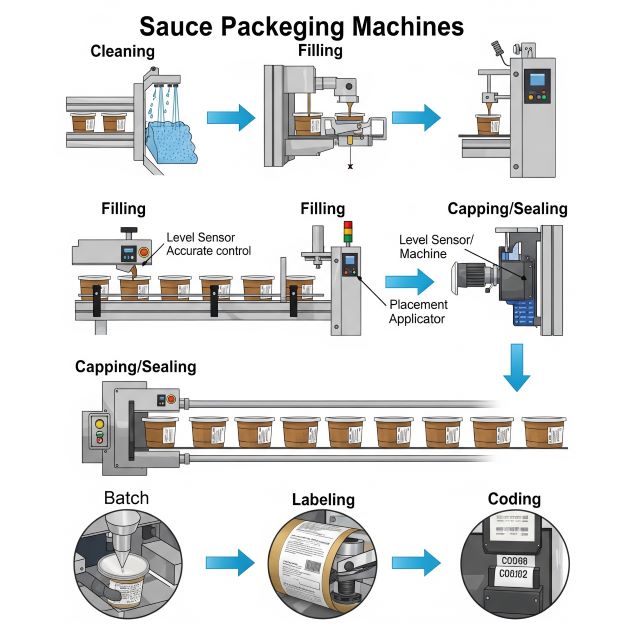

Ngabe kusebenza kanjani imishini yokupakisha yeSauce?

Ake sibheke ukuthi inqubo ephelele isebenza kanjani ngesinyathelo ngesinyathelo:

Ukuhlanza : Amabhodlela kanye nezimbiza zifaka isiteshi sokuvusa ukuze ususe uthuli

Ukugcwaliswa : Umshini wokugcwalisa weSauce udlulisela inani elifanele le-sauce

Ukukhonkotha / ukubekwa uphawu : Amabhodlela asetshenziswa, futhi izimbiza zingavalwa ngokushisa

Ukulebula : Amalebula womkhiqizo asetshenziswa ngokuzenzakalelayo

Amakhodi : Izinombolo ze-Batch nezinsuku zokuphelelwa yisikhathi ziphrintiwe

Zonke lezi zinyathelo zingenzeka emgqeni owodwa oqhubekayo. Izinzwa ziqinisekisa ukuthi iziqukathi ziyaqondaniswa futhi zigcwaliswe kahle. Iningi lezinhlelo zihlelekile. Lokhu kusho ukuthi ungabeka amazinga okugcwalisa noma amalebula ezikhundleni kalula.

Izinzuzo Zokuhlanganiswa Kwesistimu

Lapho imishini ixhumeke, basebenza ngokushesha okukhulu. Ama-opharetha awadingi ukuthinta umkhiqizo. Uthola:

Imishini yesimanje ifaka phakathi izikhala zokuthinta isikrini. Abanye banikela ngokuqapha okukude ngefu.

Izici ezibalulekile okufanele ucabangele lapho ukhetha umshini wokufaka we-sauce

Akuwona wonke umshini olingana nokusebenza konke. Nakhu okufanele ukukucabangele.

Izinhlobo zeziqukathi zeSauce

Izihloko zakho ezitsheni. Ehlukile

| Imishini |

Yonga |

| Izimbiza ze-Glass |

Piston filler, isikulufa / chuck capper |

| Amabhodlela epulasitiki |

I-Flow Filler, Snap Capper |

| Izipuni zokusukuma |

I-Volumetric Filler, Pouch Sealer |

Qiniseka ukuthi umugqa wakho wokupakisha usekela ukwakheka kwesitsha sakho nosayizi.

Izidingo zejubane lokukhiqiza

Balinganisa ukuthi zingaki amayunithi owadingayo ngehora. Amabhizinisi amancane angadinga kuphela ama-500. Amafektri amakhulu adinga i-10,000 +.

| Uhlobo lohlobo lomshini |

lungahle |

lube njalo |

| Umsebenzi wezandla |

<500 amayunithi / ihora |

Ukuqalisa, Ukuhlolwa Kusebenza |

| Semi-othomathikhi |

Amayunithi / ama-200-2000 / ihora |

Abakhiqizi abancane abaphakathi |

| Okuzenzakalelayo ngokuphelele |

Amayunithi / amayunithi / ihora lehora le-10,000 + |

Abakhiqizi abakhulu |

Khetha ngokususelwa kuzinga lakho lokukhiqiza okuhlosiwe.

Ukunemba nokunemba

Ukugcwalisa okunembile kuqinisekisa yonke ibhodlela elinemali efanele. Lokhu kwakha ukwethembana nokunciphisa imfucuza. Funa i:

Ukulungiswa nokuqina

Imishini isebenza nsuku zonke. Bheka ozimele oqinile, izingxenye zensimbi ezingenasici, kanye nemiklamo ehlanzekile elula. Izici zokubeka phambili:

Ukulungiswa kwamathuluzi mahhala

Kulula-ukushintsha ama-nozzles noma amabhande

Ukuxilongwa okwakhelwe ngaphakathi

Khetha umphakeli onikezela ngensizakalo yangemva kokuthengisa nezingxenye ezisele.

Imishini ye-automation vs.

Imishini ezenzakalelayo ezenzakalelayo ibiza okuningi kepha gcina umsebenzi. Imishini yezandla noma ye-semi-othomathikhi ishibhile futhi ivumelana nezimo.

Buza:

Ngabe ukukhiqizwa kuzokhula?

Ngabe sidinga isikhathi sokuphumula?

Ngabe abasebenzi baqeqeshelwe ukusebenza ngezinhlelo ezenziwa nge-automateated?

I-automation ithuthukisa ukuphuma nokuvumelana. Ikhokha ngesikhathi eside.

Izinzuzo zokusebenzisa imishini yokupakisha ye-Sauce ebhizinisini lakho

Ukusebenza Kakhulu

Gcwalisa imishini, cap, kanye nelebula ngokushesha kunabantu. Banciphisa ukukhathala komuntu nephutha.

Ukuvumelana kanye nokulawulwa kwekhwalithi

Wonke amabhodlela noma imbiza kubukeka okufanayo. Inani le-Sauce liqondile. Amalebula awabizi. Ukukhonkotha kuyafana. Lokhu kwakha ukwethenjwa komkhiqizo.

Ukonga izindleko

Ungonga ukusebenza. Wehlisa usoso. Ugwema izikhalazo zamakhasimende ezivela emabhodleleni angaphansi komhlaba. Konke lokhu kuthuthukisa imishado yenzuzo.

Impilo engcono yeshelufu nokuvikelwa komkhiqizo

Izimbiza ezivaliwe zihlala isikhathi eside. Amasoso agcwele ama-vacuum ahlala okusha. Ukungcola kuncishisiwe.

Imikhiqizo kanye nokumaketha izinzuzo

Ukupakishwa kwakho kubukeka kuchwepheshe. Amalebula asiza ukuqashelwa komkhiqizo. Izinsuku zokuphelelwa yisikhathi zikugcina uthobela.

Abakhiqizi be-Pauce Packing Machine abakhiqizi abaphezulu

I-Tengzhuo: Umshini wokupakisha womshini ohola phambili

I-Tengzhuo yenza ethembekile futhi ethembekile imishini yokupakisha . Umugqa womkhiqizo wabo ufaka:

Imishini yokugcwalisa ama-piston for sauces obukhulu

Ukugoqa nemishini yokubopha uphawu

Qedela imigqa yokupakisha ephelele

Izinzuzo:

Imiklamo ehlanganisiwe

Izindawo ezisebenziseka kalula

Ukusekelwa kwezimbiza zengilazi, amabhodlela ezilwane zasekhaya, kanye nezipuni

UTengzhuo unikeza ukuthumela komhlaba jikelele nokuphendula kwamakhasimende.

Ungayigcina kanjani imishini yakho yokupakisha ye-Sauce

Amathiphu Wokulondolozwa Okujwayelekile

Hlanza ama-nozzles nsuku zonke

Hlola amabhande nezimpawu masonto onke

Faka esikhundleni izingxenye ezigqokwa ngokushesha

Sebenzisa izithambisi eziphephile zokudla. Gcina irekhodi lomshini ngamunye.

Ukuxazulula Izinkinga ezijwayelekile

| kubangela |

isixazululo |

inkinga |

| Ukugcwaliswa okungahambelani |

Ama-Bubble e-AIR, ama-Pistons agqokile |

Iphinda kabusha noma buyisela ama-pistons |

| Izibuko ze-Leaky |

Ukushisa okuphansi, ama-sealers abhalwe kabi |

Lungisa izinga lokushisa uphawu noma ukuvumelanisa |

| Faka ilebula ukungafaneleki |

Ama-roller agqokwa, amaphutha |

Ama-roller ahlanzekile, hlola ilebula feed |

Ukugcina

Umshini wokupakisha we-Sauce uqinisa isivinini sokukhiqiza, ikhwalithi yomkhiqizo, nokuvumelana. Kunciphisa amaphutha, kukhulisa impilo yeshalofu, futhi kuthuthukise uphawu. Emibhalweni yokugcwalisa ye-sauce ukuletha amalebula nezinhlelo zokukhonkotha, yonke ingxenye idlala indima ebalulekile.

Hlola uhlobo lwakho lwesiqukathi, izidingo zokukhiqiza, kanye nezinga le-automation. Khetha umphakeli othembekile. Gcina imishini yakho njalo. Lezi zinyathelo ziqinisekisa umugqa wokukhiqiza onenzuzo nobushelelezi.

Unesifiso sokukala ibhizinisi lakho le-sauce? Thintana I-Tengzhuo noma umphakeli othembekile wesixazululo esilinganiselwe.

Umthandi

Yimuphi umshini wokupakisha we-Sauce omuhle kakhulu wamabhizinisi amancane?

Ama-piston ama-piston ama-piston abhangqiwe ngama-chappers wezandla. Ziyabiza futhi zivumelana nezimo.

Ngiwukhetha kanjani umshini wokugcwalisa we-sauce ofanele?

Cabanga nge-sauce viscosity, uhlobo lwesiqukathi, nesivinini sokuphuma. Ama-piston fillers asebenza kangcono ngosososi obukhulu.

Ingabe imishini yokupakisha ye-Sauce ingahle ibekwe ngezifiso izinhlobo ezahlukene ze-sauce?

Yebo. Abahlinzeki abaningi banikela ngemishini enezilungiselelo eziguqukayo ze-viscosities ezahlukahlukene kanye namavolumu.

Yiziphi izingqinamba ezivamile ngemishini yokupakisha ye-Sauce futhi ingalungiswa kanjani?

Izinkinga ezijwayelekile zifaka ukuvuza, amaphutha amaphutha, kanye nokulebula amaphutha. Ukulungiswa okujwayelekile kanye nengxenye yezingxenye ezibekelwe indawo yokubuyisa izinkinga eziningi.

Ungaba nentshisekelo ngesihloko esifanayo

Umhlahlandlela wokugcina wokugcwalisa imishini yezimonyo

Umhlahlandlela wokugcina we-Pouch Paking Machines: Izinhlobo, izinzuzo, kanye namathiphu wokuthenga

Izinhlobo zemishini yokuvalwa uphawu: Izinhlobo eziyi-13 zokupakisha imishini yokubopha uphawu

Umhlahlandlela wokugcina wokukhetha umshini wekhofi ofanele