T: +86-189-2891-8174

E: wechupack@yeah.net

E: wechupack@yeah.net

104 The Second Building, No.43 Haichong Road, Shiqi Town,Panyu District, Guangzhou City, China

Views: 0 Author: Site Editor Publish Time: 2025-06-13 Origin: Site

In today's fast-paced world, food packaging machines play a crucial role in the food industry. They help businesses package products efficiently, ensuring quality and extending shelf life. Whether it’s snacks, beverages, or ready meals, packaging is a vital part of food preservation and presentation. This guide will take you through the types of food packaging machines, their benefits, and the technology behind them. Understanding these machines can help you make the best decisions for your business, whether you're looking to optimize production, reduce costs, or meet environmental standards.

A food packaging machine is a piece of equipment designed to automate the process of packing food items into containers for transport, storage, and sale. The role of these machines is to maintain the quality of food, enhance product appeal, and ensure the packaging process is efficient and consistent. Different types of machines are available to suit various food products, from granular items like grains to liquids and perishable products.

There are two primary categories of food packaging machines:

Form-fill-seal machines: These machines use roll-stock packaging material, forming bags, filling them with product, and sealing the bags. They are ideal for products such as grains, powdered foods, and liquids.

Premade pouch sealing machines: These machines fill pre-formed pouches, sealing them afterward. They are often used for products like sauces, snacks, and frozen foods.

Both FFS machines and premade pouch sealing machines require heat sealing mechanisms to thermally seal the packaging materials. Heat sealing methods can include flat plate, roller, belt, sliding clamp, and melting cut mechanisms. These methods ensure that the packaging materials are sealed with the appropriate pressure, temperature, and timing to maintain food quality and freshness.

A flow wrapping machine is often referred to as a horizontal flow wrapping machine. This type of food packaging machine is widely used for products like cookies, candy bars, and snack bars. These machines create a continuous flow of packaging material that wraps around individual items. The main benefits of flow wrapping include speed and efficiency, which can significantly boost production rates.

Flow wrapping machines can handle a variety of packaging types, such as pillow packs and stand-up pouches, making them versatile. Some advanced models incorporate vision technology to ensure precise alignment and automatic print inspection, ensuring the highest packaging quality.

VFFS machines are highly efficient for packing granular or powdered products. They form, fill, and seal bags in a single vertical process. Food packaging machines like these are perfect for snacks, grains, coffee, and other dry goods. Some advanced VFFS systems use servo controls to regulate the speed and accuracy of the bag formation. They can also handle different bag styles, including pillow bags, shaped bags, and stand-up pouches.

The ability to integrate these machines into a larger production line makes them an excellent choice for high-volume packaging operations. These machines typically offer quick changeovers and user-friendly interfaces, ensuring minimal downtime during production.

Thermoforming machines are used to create custom-shaped packaging from plastic sheets, ideal for products that require specific shapes or compartmentalized packaging. These machines are often used for meat, poultry, seafood, and dairy products. Thermoforming machines heat plastic sheets to a specific temperature and then press them into molds, forming containers that are perfect for holding food items securely.

These machines can also be integrated into bottling or canning lines for beverages. The addition of robotic automation and inspection systems in modern thermoforming machines enhances hygiene standards and production efficiency.

A sachet packaging machine automatically produces small, square, or rectangular sachets with a four-side seal. These are perfect for products like ketchup, spices, salt, and sugar. The high-speed production capability of these machines, producing 100-120 sachets per minute, makes them ideal for large-scale operations.

In addition to four-side sachets, some machines can also produce stick packs, three-side seal sachets, and pouches with tear-notches. These machines are flexible enough to handle free-flowing products, liquids, and pastes.

Tray sealing machines are essential for packaging ready meals, fresh produce, and other food items that require secure and protective seals. These machines create a tight seal around the tray, ensuring the freshness of the food inside. Some tray sealing systems come equipped with modified atmosphere packaging (MAP) technology, which helps extend the shelf life of fresh and perishable products.

This type of machine is popular in grocery stores and supermarkets for packaging products like salads, fresh meats, and convenience meals. The ability to handle various tray shapes and materials makes tray sealing machines versatile and ideal for many different food packaging applications.

A cartoning machine automates the process of forming, filling, and sealing cartons. These machines are often used for secondary packaging of individually wrapped products or creating retail-ready packaging. They can handle a variety of carton sizes and styles, making them suitable for products like breakfast sandwiches, burritos, and bakery goods.

Modern cartoning machines often feature robotic pick-and-place technology and vision systems for precise product handling and quality control. This automation reduces errors and increases efficiency in packaging processes.

Shrink wrapping machines are used to create tight, tamper-evident seals, particularly for multi-packs or oddly shaped products. These machines work by applying heat to shrink the film tightly around the product, creating a durable seal. Shrink wrapping is ideal for items that need to be bundled together for transport or for products that require enhanced protection during storage and display.

These machines can handle a wide range of product sizes and shapes, making them a versatile solution for businesses needing a packaging solution that offers both protection and attractive retail presentation.

Vacuum packaging machines remove air from the package before sealing, which helps preserve the freshness and extend the shelf life of food items. This technology is particularly useful for meats, cheeses, and other perishable products that need to be stored for extended periods.

Modern vacuum packaging systems often incorporate modified atmosphere packaging (MAP), and they can handle a variety of packaging materials to optimize protection. These machines are crucial for reducing food wastage and ensuring that products remain fresh longer.

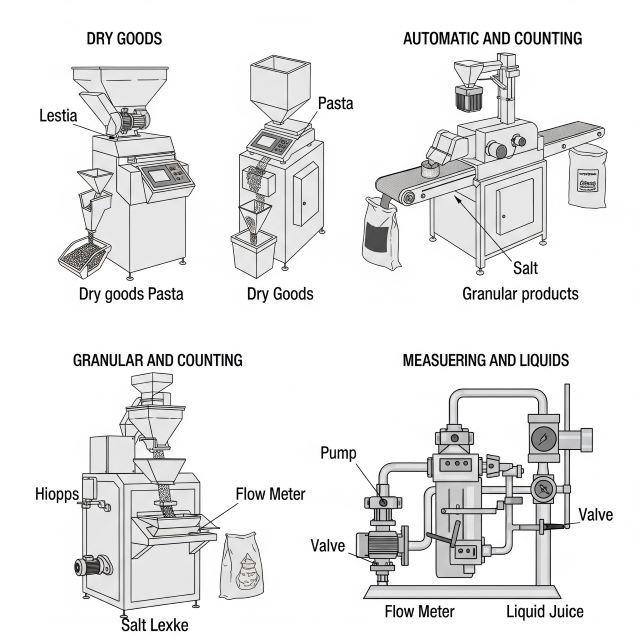

Automatic weighing and counting machines are essential for accurately dispensing food products into packages. These machines use advanced technologies such as load cells and volumetric fillers to ensure precise measurement, minimizing waste and ensuring compliance with industry standards. They are commonly used for dry goods, granular products, and liquids.

The ability to integrate these machines with other food packaging equipment enhances efficiency, allowing businesses to achieve high-speed filling while maintaining accuracy and consistency.

While not strictly a food packaging machine, labelling machines are an essential part of the food packaging process. These machines apply labels, barcodes, and other important product information to the packaging. They help ensure the correct product identification, traceability, and compliance with regulatory requirements.

Many modern labelling machines incorporate vision technology for quality control, ensuring that labels are applied correctly every time. They can also integrate with thermal inkjet printers for printing codes, dates, and batch numbers, making them invaluable for businesses that require high-quality, accurate labeling.

One of the main benefits of food packaging machines is the significant boost in production efficiency. These machines can work continuously, reducing the need for manual labor and increasing output without compromising quality. With automation, businesses can meet high demand more effectively.

Automating the packaging process ensures that every item is packaged to the same high standard. This consistency is crucial in maintaining the quality of food products and meeting customer expectations.

Packaging machines that incorporate modified atmosphere packaging (MAP) or vacuum sealing play a crucial role in extending the shelf life of food products. These technologies reduce spoilage and preserve freshness, leading to reduced food wastage.

While the initial investment in food packaging machines can be high, the long-term savings are significant. By reducing the reliance on manual labor, improving production rates, and minimizing packaging errors, businesses can achieve better profitability.

Many food packaging machines now come equipped with features that reduce waste and use eco-friendly packaging materials. Companies can choose biodegradable or recyclable films and materials to align with sustainability goals.

Sustainability is becoming an increasingly important factor in food packaging. Food packaging machines have evolved to include features that help reduce environmental impact, such as using recyclable materials and minimizing energy consumption.

Many modern machines are designed to optimize resource use, reduce waste, and minimize energy consumption during operation. For instance, vacuum packaging machines help reduce food waste by extending shelf life, while flow wrapping and sachet machines can use biodegradable films to reduce plastic waste.

Modern food packaging machines incorporate advanced technologies such as vision inspection systems, robotic automation, and AI-based control systems. These innovations enable packaging lines to operate faster, more efficiently, and with higher precision. Automation also ensures better consistency in packaging, reducing human errors and improving product quality.

Technologies like IoT (Internet of Things) allow businesses to monitor and control packaging machines remotely, making it easier to optimize performance and reduce downtime. These advances are helping to drive innovation in the packaging industry.

Choosing the right food packaging machine involves several considerations:

Type of food: Different foods require different packaging methods. For instance, granular products may require VFFS machines, while perishable goods may need vacuum packaging.

Production volume: High-volume operations require high-speed machines with quick changeover capabilities.

Packaging style: Consider the type of packaging (e.g., pouches, cartons, sachets) you need.

Budget: Balance your investment with the expected return on investment (ROI) based on your production needs.

Maintenance: Look for machines with low maintenance needs and easy access for repairs.

The future of food packaging machines is exciting. Innovations like smart packaging, sustainability, and robotics are shaping the future of the industry. Machines are becoming more automated, precise, and eco-friendly, helping businesses meet evolving consumer demands and stay competitive.

Advances in AI and robotics will continue to streamline packaging processes, reducing labor costs and improving efficiency. Meanwhile, the demand for sustainable packaging solutions will drive the development of new technologies that use fewer resources and produce less waste.

Choosing the right food packaging machine can significantly enhance your business’s production efficiency, reduce costs, and improve product quality. Whether you're packaging dry goods, perishable foods, or beverages, there is a wide range of machines to meet your needs. Stay ahead of industry trends by investing in the right technology, and consider factors like sustainability and automation when making your decision.

The Ultimate Guide To Filling Machines for Cosmetics

The Ultimate Guide To Pouch Packing Machines:Types,Benefits,And Buying Tips

Types of Sealing Machines: 13 types of Packaging Solutions Sealing Machines

The Ultimate Guide To Choosing The Right Coffee Packaging Machine