Emhlabeni wanamuhla osheshayo, imishini yokupakisha yokudla idlala indima ebalulekile embonini yokudla. Basiza amabhizinisi ephakethe imikhiqizo kahle, aqinisekisa ikhwalithi nokunweba impilo yeshelufu. Noma ngabe kungukudla okulula, iziphuzo, noma ukudla okulungele, ukupakisha kuyingxenye ebalulekile yokulondolozwa kokudla kanye nesethulo. Lo mhlahlandlela uzokuthatha ngezinhlobo zemishini yokupakisha yokudla , izinzuzo zawo, kanye nobuchwepheshe obabekile. Ukuqonda le mishini kungakusiza ukuthi wenze izinqumo ezinhle kakhulu zebhizinisi lakho, noma ngabe ufuna ukukhiqiza, ukunciphisa izindleko, noma uhlangabezane namazinga wezemvelo.

Uyini umshini wokupakisha wokudla?

Umshini wokupakisha wokudla ucezu lwemishini eyenzelwe ukushintsha inqubo yokupakisha izinto zokudla ezitsheni zokuhamba, ukugcinwa, nokuthengisa. Iqhaza lale mishini ukugcina ikhwalithi yokudla, ukuthuthukisa isikhalazo somkhiqizo, futhi siqinisekise ukuthi inqubo yokupakisha iyasebenza futhi iyavumelana. Izinhlobo ezahlukene zemishini ziyatholakala ukuze zivumelane nemikhiqizo ehlukahlukene yokudla, kusuka ezintweni ze-granur ezinjengezinhlamvu ku-ketshezi nemikhiqizo engonakala.

Kunezigaba ezimbili zokuqala zemishini yokupakisha yokudla :

yokugcwalisa ifomu Imishini Zilungele imikhiqizo efana nezinhlama, ukudla okungumpuphu, kanye noketshezi.

Imishini yokuvalwa kwesikhwama sePremining : Le mishini igcwalisa amapayipi okwakheka ngaphambili, ibala uphawu kuyo ngemuva kwalokho. Zivame ukusetshenziselwa imikhiqizo efana namasoso, ukudla okulula, nokudla okuqandisiwe.

Izindlela zokushisa zokushisa kwamafilimu epulasitiki

Yomibili le mishini ye-FFS kanye nemishini yokuvalwa kwesikhwama sePrepade idinga izindlela zokushisa zokushisa ukuze zinciphise izinto zokupakisha. Izindlela zokushisa zokushisa zingafaka i-flat poller , beller , bliding clamp , sliding clamp , kanye nezinqubo zokunciphisa ezincibilikisiwe . Lezi zindlela ziqinisekisa ukuthi izinto zokupakisha zibekwa uphawu ngengcindezi efanelekile, izinga lokushisa kanye nesikhathi sokugcina ikhwalithi yokudla kanye nokusha.

Izinhlobo ezibalulekile zemishini yokupakisha yokudla

Flow ukugoqa umshini wokupakisha wokudla

Umshini we-Flow Wording uvame ukubizwa ngokuthi umshini wokugoba ovundlile. Lolu hlobo lomshini wokupakisha wokudla lusetshenziselwa kakhulu imikhiqizo efana namakhukhi, imigoqo ye-candy, nemigoqo yokudla okulula. Le mishini yakha ukugeleza okuqhubekayo kwezinto zokufaka ezimboza izinto ngazinye. Izinzuzo eziphambili zokugoqwa kokugeleza zifaka ijubane nokusebenza kahle, okungakhulisa amanani okukhiqiza okukhulu.

Imishini yokugoqa yokugeleza ingaphatha izinhlobo ezahlukene zokupakisha, njengephakethe lomcamelo nezipuni zokusukuma , zizenze ziguquguquke. Amanye amamodeli athuthukile afaka ubuchwepheshe bokubona ukuqinisekisa ukuhambisana okuqondile kanye nokuhlola okuzenzakalelayo, ukuqinisekisa ikhwalithi ephezulu kakhulu yokufaka.

IFOMU LOFFICAL FOX FAGE FAGCE (VFFS) Imishini

Imishini ye-VFFS isebenza kahle kakhulu ngokupakisha imikhiqizo ye-granular noma eyimpuphu. Bakha, bagcwalisa, futhi basayine izikhwama kwinqubo eyodwa ebheke mpo. Imishini yokupakisha yokudla efana nale ilungele ukudla okulula, okusanhlamvu, ikhofi, nezinye izimpahla ezomile. Ezinye izinhlelo ezithuthukile ze-VFFS zisebenzisa izilawuli ze-servo ukulawula ijubane nokunemba kokwakheka kwesikhwama. Bangakwazi futhi ukuphatha izitayela ezihlukile zesikhwama, kufaka phakathi izikhwama zomcamelo , izikhwama ezakhiwe , nezindawo zokusukuma.

Amandla okuhlanganisa le mishini emugqeni omkhulu wokukhiqiza abenza babe ukukhetha okuhle kakhulu kwemisebenzi epakishe ephezulu. Le mishini ngokuvamile inikela ngama-evover asheshayo kanye nokuxhumana okusebenziseka kalula, ukuqinisekisa isikhathi esincane sokuphumula ngesikhathi sokukhiqiza.

Imishini yokufaka i-Thermoforming

I-Thermoforming imishini isetshenziselwa ukudala ukufakwa okwenziwe ngokwezifiso kusuka kumashidi epulasitiki, elungele imikhiqizo edinga ukwakheka okuthile noma ukufakwa okuhlanganisiwe. Le mishini ivame ukusetshenziselwa inyama , yenkukhu , yokudla kwasolwandle , nemikhiqizo yobisi . Imishini yokufaka ukushisa ukushisa amashidi epulasitiki ekushiseni okuthile bese ucindezela kubo ekubumbeni, kwakheka iziqukathi ezilungele ukubamba izinto zokudla ngokuphephile.

Le mishini nayo ingahlanganiswa emigqeni yokubhoma noma yokuwafaka iziphuzo. Ukwengezwa kwezinhlelo ze-robotic ezenzakalelayo nezinhlelo zokuhlola emishinini yesimanje yokufaka ama-thermoforming kuthuthukisa amazinga wokuhlanzeka kanye nokusebenza kahle kokukhiqiza.

Imishini yokupakisha yeSachet

Umshini wokupakisha we-sachet ukhiqiza ngokuzenzakalelayo, noma ama-sachets amancane, noma amanxeba ane-seal enamahlandla amane. Lokhu kulungele imikhiqizo efana ne -ketchup , spices , usawoti , noshukela . Amandla okukhiqiza ashesha kakhulu wale mishini, akhiqiza ama-sachets ayi-100-120 ngomzuzu, abenze abe efanelekile yokusebenza okukhulu.

Ngaphezu kwama-sachets aseceleni amane , eminye imishini ingakhiqiza futhi i-stick ipaka , ama-sachets we-seal-Side amathathu , kanye nezikhwama ezinama-tear-notches. Le mishini ivumelana nezimo ngokwanele ukuphatha imikhiqizo egeleza mahhala, uketshezi, kanye nama-pastes.

Imishini yokubopha uphawu kweTray

Imishini yokubopha uphawu nge-Tray ibalulekile ukupakisha ukudla okulungele , ukukhiqizwa okusha , nezinye izinto zokudla ezidinga izibuko eziphephile nezivikelayo. Le mishini yakha uphawu oluqinile oluzungeze ugqoko, luqinisekisa ubusha bokudla ngaphakathi. Ezinye izinhlelo zokubopha uphawu lwe-Tray zihlome nge- Addified Atmost Ackaiging Paka (Map) Technology, esiza ukunweba impilo yeshalofu yemikhiqizo emisha neyonke.

Lolu hlobo lomshini luyathandwa ezitolo zokudla kanye nezitolo ezinkulu zemikhiqizo yokupakisha efana namasaladi, inyama entsha, nokudla okulula. Amandla okuphatha ukwakheka kwe-tray ehlukahlukene nezinto zokwakha enza imishini yokubopha uphawu ye-tray eguquguqukayo futhi elungele izinhlelo eziningi zokupakisha zokudla ezahlukahlukene.

Imishini yokuqamba

Umshini we-cartoning asebenzisa inqubo yokwakha, ukugcwalisa, kanye namabhokisi okubopha uphawu. Le mishini ivame ukusetshenziselwa ukufakwa kwesibili kwemikhiqizo ngayinye esongwe noma ukudala ukuthengiswa okulungele izitolo . Bangakwazi ukuphatha izinhlobo ezahlukene ze-carton osayizi nezitayela, zibenze balungele imikhiqizo efana ne yasekuseni , -burmiches , nezimpahla zokubhaka.

Imishini yanamuhla ye-cartoning ivame ukufaka be-robotic thwer-and-Beka indawo nezinhlelo ubuchwepheshe zombono zokuphathwa komkhiqizo okuqondile nokulawulwa kwekhwalithi. Lokhu okuzenzakalelayo kunciphisa amaphutha futhi kwandise ukusebenza kahle ezinhlelweni zokupakisha.

Shrink ukugoqa amasistimu

Imishini yokugoqa ye-Shrink isetshenziselwa ukudala izimbumbulu eziqinile, ze-tamper-ezibonakalayo, ikakhulukazi kumaphakethe amaningi noma imikhiqizo ebekiwe. Le mishini isebenza ngokusebenzisa ukushisa ukuncipha i-film ngokuqinile ezungeze umkhiqizo, kwakha uphawu oluqinile. Ukugoqeka kwe-Shrink kulungele izinto ezidinga ukuhlanganiswa ndawonye ukuze zithuthe noma zemikhiqizo edinga ukuvikelwa okuthuthukile ngesikhathi sokugcina nokuboniswa.

Le mishini ingaphatha uhla olubanzi losayizi womkhiqizo nobukhulu, okwenza kube yisixazululo esiguquguqukayo samabhizinisi adinga isixazululo sokufaka esinikeza ukuvikelwa kanye nesethulo sokuthengisa esikhangayo.

Imishini yokupakisha ye-vacuum

Imishini yokupakisha ye-vacuum isuse umoya kusuka kwiphakheji ngaphambi kokubekwa uphawu, okusiza ukugcina ubusha bese kunweba impilo yeshelufu yezinto zokudla. Lobu buchwepheshe buwusizo ikakhulukazi benyama , kubashizi , neminye imikhiqizo engonakalayo edinga ukugcinwa isikhathi eside.

Izinhlelo zesimanje zokupakisha i-vacuum zivame ukufaka ukupakishwa komkhathi oguquliwe (Imephu) , futhi bangakwazi ukuphatha izinto ezahlukene zokupakisha ukwenza ngcono ukuvikelwa. Le mishini ibalulekile ekunciphiseni imfucumfucu yokudla kanye nokuqinisekisa ukuthi imikhiqizo ihlala intsha isikhathi eside.

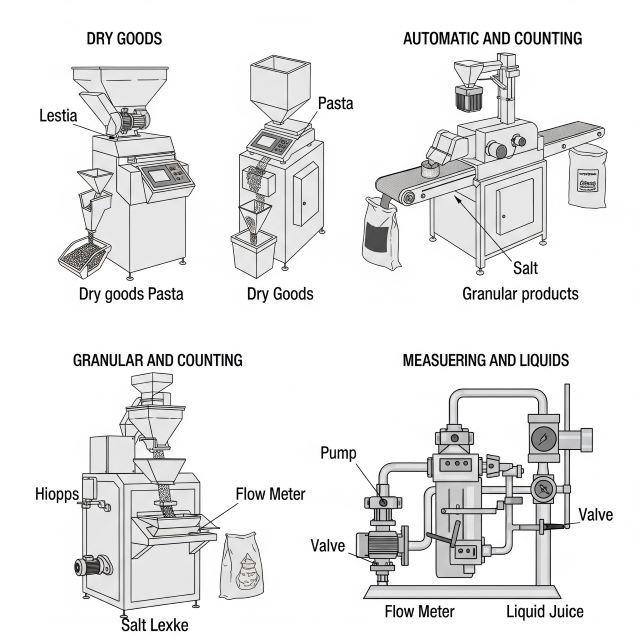

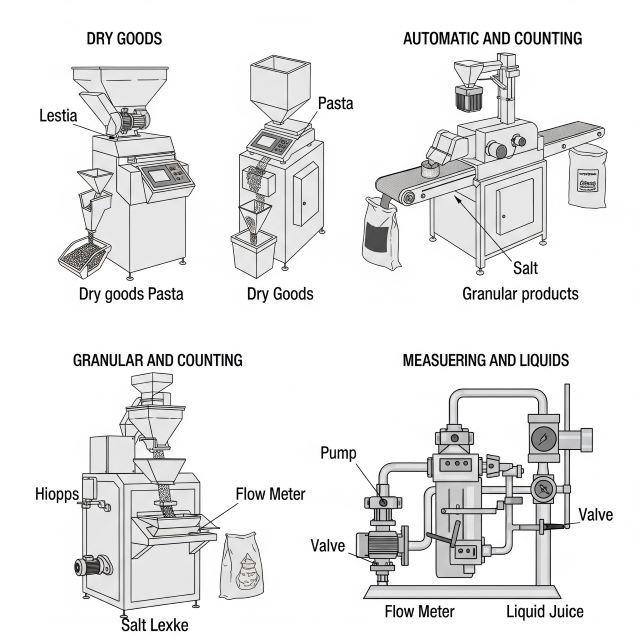

Imishini enesisindo esizenzakalelayo kanye nokubala

okuzenzakalelayo kanye nokubala Imishini yokubala ibalulekile ekusakazeni ngokunembile imikhiqizo yokudla kumaphakeji. Le mishini isebenzisa ubuchwepheshe obuthuthukile njengamaseli omthwalo nama -volumetric filler ukuqinisekisa ukulinganisa okuqondile, ukunciphisa imfucuza kanye nokuqinisekisa ukuhambisana namazinga ezimboni. Zivame ukusetshenziswa emikhiqizweni eyomile ye- , granular granular , kanye noketshezi.

Amandla okuhlanganisa le mishini nezinye izinto zokufaka ukudla zithuthukisa ukusebenza kahle, okuvumela amabhizinisi ukufeza ukugcwaliswa ngejubane eliphezulu ngenkathi kugcinwa ukunemba nokungaguquguquki.

Imishini yokulebula

Yize kungewona ngokuqinile imishini yokudla kwemishini yokudla , yokufaka ilebula kuyingxenye ebalulekile yenqubo yokupakisha yokudla. Le mishini isebenzisa ama-labels , ama-barcode , kanye neminye imininingwane ebalulekile yomkhiqizo kwiphakheji. Basiza ekuqinisekiseni ukukhonjwa komkhiqizo okulungile, ukulandelela, kanye nokuhambisana nezidingo zokulawula.

Imishini eminingi yanamuhla yokulebula ifaka ubuchwepheshe bokubona kokulawulwa kwekhwalithi, ukuqinisekisa ukuthi amalebula asetshenziswa kahle ngaso sonke isikhathi. Bangakwazi futhi ukuhlanganisa nabaphrinti be-inkjet abashisayo kumakhodi wokuphrinta, izinsuku nezinombolo ze-batch, ezibenza bagxile kumabhizinisi adinga ukubhala okuphezulu, okunembile.

Izinzuzo zokusebenzisa imishini yokupakisha yokudla

1. Ukusebenza Kakhulu

Enye yezinzuzo eziphambili zemishini yokufaka ukudla ingukukhulisa okubalulekile ekusebenzeni kahle kokukhiqiza. Le mishini ingasebenza ngokuqhubekayo, yehlisa isidingo sokusebenza okwenziwa ngesandla kanye nokwanda kokuphuma ngaphandle kokuyekethisa ikhwalithi. Nge-automation, amabhizinisi angahlangabezana nokufunwa okuphezulu ngempumelelo.

2. Ukuvumelana kanye nokulawulwa kwekhwalithi

Ukuguqula inqubo yokufaka kuqinisekisa ukuthi yonke into ihlanganiswe ezingeni elifanayo elifanayo. Lokhu kuvumelana kubalulekile ekugcinweni kwekhwalithi yemikhiqizo yokudla nokuhlangabezana nokulindelwe kwamakhasimende.

3. Impilo eshehle enwetshiwe

Imishini yokupakisha efaka ukufakwa komkhathi okuguquliwe (Imephu) noma ukubekwa uphawu kwe-vacuum kudlala indima ebalulekile ekwandiseni impilo yeshelufu yemikhiqizo yokudla. Lezi zibuchwepheshe zinciphisa ukuchitheka futhi zigcine okusha, okuholela ekunciphiseni imfucumfucu yokudla.

4. Ukonga izindleko

Ngenkathi ukutshalwa kwezimali kokuqala emishinini yokupakisha yokudla kungaphezulu, ukonga isikhathi eside kubalulekile. Ngokunciphisa ukuthembela ekusebenzeni kwezandla, ukwenza ngcono amanani okukhiqiza, kanye nokunciphisa amaphutha wokupakisha, amabhizinisi angafinyelela inzuzo engcono.

5. Izinketho ze-Eco-Friendly

Imishini eminingi yokufaka ukudla manje iza ifakwe izici ezinciphisa imfucuza futhi zisebenzise izinto zokupakisha ezinobungane. Izinkampani zingakwazi ukukhetha amafilimu angenakusebenza noma angaphinde asebenze kabusha nezinto zokwakha ukuvumelanisa nezinhloso zokusimama.

Indlela imishini yokupakisha yokudla ifaka isandla ekuqinisekiseni

Ukusimama kuba yinto ebaluleke kakhulu ekuphaketheni kokudla. Imishini yokupakisha yokudla iye yavela ukufaka izici ezisiza ukunciphisa umthelela wezemvelo, njengokusebenzisa izinto eziphindaphindekile futhi kunciphisa ukusetshenziswa kwamandla.

Imishini eminingi yesimanje yenzelwe ukwengeza ukusetshenziswa kwezinsizakusebenza, ukunciphisa imfucuza, futhi inciphise ukusetshenziswa kwamandla ngesikhathi sokusebenza. Isibonelo, imishini yokupakisha ye-Vacuum iyasiza ukunciphisa imfucumfucu yokudla ngokunweba impilo yeshelufu, ngenkathi ukugoqwa kokugeleza nemishini ye-sachet ingasebenzisa amafilimu e-bioderbradable ukunciphisa imfucuza egcwele.

Ubuchwepheshe ngemuva kwemishini yesimanje yokupakisha yokudla

Imishini yesimanje yokupakisha yokudla ifaka ubuchwepheshe obuphambili obufana nezinhlelo zokuhlola umbono , ama-robotic automation automation , kanye nezinhlelo zokulawula ezenzelwe i-AI . Lezi ezintsha zinika amandla ukupakisha imigqa ukusebenza ngokushesha, ngempumelelo, futhi ngokunemba okuphezulu. I-automation ibuye iqinisekise ukuvumelana okungcono kokupakisha, ukunciphisa amaphutha abantu kanye nokwenza ngcono ikhwalithi yomkhiqizo.

Ubuchwepheshe obufana ne -IOT (I-Intanethi Yezinto) bavumele amabhizinisi ukuthi aqaphe futhi alawule imishini yokupakisha ukude, okwenza kube lula ukwenza kahle ukusebenza futhi kunciphise isikhathi sokuphumula. Le nqubekela phambili isiza ukushayela izinto ezintsha embonini yokufaka.

Ungawukhetha kanjani umshini wokupakisha wokudla ofanele webhizinisi lakho

Ukukhetha umshini wokupakisha ofanele wokudla kubandakanya ukucatshangelwa okuningana:

Uhlobo lokudla : Ukudla okuhlukile kudinga izindlela ezahlukahlukene zokupakisha. Isibonelo, imikhiqizo ye-granular ingadinga imishini yama-VFFS, ngenkathi izimpahla ezishabalalayo zingadinga ukufakwa kwe-vacuum.

I-Production Provolul : Ukusebenza kwevolumu ephezulu kudinga imishini esheshayo enamakhono asheshayo wokushintsha.

Isitayela sokupakisha : Cabanga uhlobo lokupakisha (isib. Ama- Pouches , Cartons , Sachets ) odingayo.

Isabelomali : Ibhalansi imali yakho ngokubuyiselwa okulindelwe ekutshalweni kwemali (ROI) ngokususelwa ezidingweni zakho zokukhiqiza.

Isondlo : Bheka imishini enezidingo zokulungiswa okuphansi kanye nokufinyelela okulula kokulungiswa.

Ikusasa lemishini yokupakisha yokudla

Ikusasa lemishini yokupakisha yokudla iyajabulisa. Ukusungulwa okufana okumakhele okuhlakaniphile , nokuma , futhi ama-robotic abumba ikusasa lomkhakha. Imishini iya ngokuya isebenza ngokuzenzakalela, inembile, futhi i-eco-friendly, ukusiza amabhizinisi ahlangane athola izimfuno zabathengi futhi aqhubeke nokuncintisana.

Intuthuko ku-AI namaRobhothi izoqhubeka nokuhambisa izinqubo zokupakisha, ukunciphisa izindleko zabasebenzi kanye nokwenza ngcono ukusebenza kahle. Ngaleso sikhathi, isidingo sezixazululo ezizinzile zokupakisha zizoshayela ukuthuthukiswa kobuchwepheshe obusha obusebenzisa izinsiza ezimbalwa futhi bakhiqize imfucuza encane.

Isiphetho: Khulisa ukusebenza kahle nekhwalithi ngomshini wokupakisha wokudla ofanele

Ukukhetha ofanele umshini wokupakisha wokudla kungakhulisa kakhulu ukusebenza kahle kwebhizinisi lakho, ukunciphisa izindleko, futhi uthuthukise ikhwalithi yomkhiqizo. Noma ngabe upakisha izimpahla ezomile , ukudla okungonakali , noma iziphuzo , kunemishini ehlukahlukene yokuhlangabezana nezidingo zakho. Hlala ngaphambi kwezindlela zomkhakha ngokutshala ubuchwepheshe obufanele, bese ubheka izici ezinjengokuzinza kanye ne-automation lapho wenza isinqumo sakho.

Ungahle futhi uthande

Umhlahlandlela wokugcina wokugcwalisa imishini yezimonyo

Umhlahlandlela wokugcina we-Pouch Paking Machines: Izinhlobo, izinzuzo, kanye namathiphu wokuthenga

Izinhlobo zemishini yokuvalwa uphawu: Izinhlobo eziyi-13 zokupakisha imishini yokubopha uphawu

Umhlahlandlela wokugcina wokukhetha umshini wekhofi ofanele