T: +86-189-2891-8174

E: wechupack@yeah.net

E: wechupack@yeah.net

104 The Second Building, No.43 Haichong Road, Shiqi Town,Panyu District, Guangzhou City, China

Views: 0 Author: Site Editor Publish Time: 2025-06-11 Origin: Site

Candy packaging machines have revolutionized the candy manufacturing industry by providing efficient, cost-effective, and high-quality solutions for packaging confectionery products. As candy production grows, the need for automated and reliable packaging systems becomes essential. This comprehensive guide will take you through everything you need to know about candy packaging machines, from how they work to their various types, benefits, and how to maintain them. Understanding these systems can help you make informed decisions to boost your business operations and product presentation.

A candy packaging machine is a specialized machine designed to automate the packaging of candies. These machines are essential in large-scale candy production and serve a variety of purposes, such as wrapping, counting, sealing, and labeling. They are designed to handle high volumes of candy products, ensuring uniformity and consistency in packaging.

The process of packaging candies manually is not only time-consuming but also prone to errors. Candy packaging machines eliminate the need for manual labor, speeding up the process, and ensuring that every product is properly packaged, sealed, and labeled with minimal human intervention. The result is a streamlined production line that increases efficiency and reduces errors.

Improved Efficiency: Automation allows machines to work around the clock, increasing production speed without sacrificing quality.

Consistent Quality: Machines maintain high standards of quality by eliminating human error.

Enhanced Hygiene: Reducing manual handling ensures a lower risk of contamination, especially when dealing with food products.

Cost Savings: Though the initial cost of a candy packaging machine can be significant, the long-term benefits of reduced labor and increased production capacity make it a sound investment.

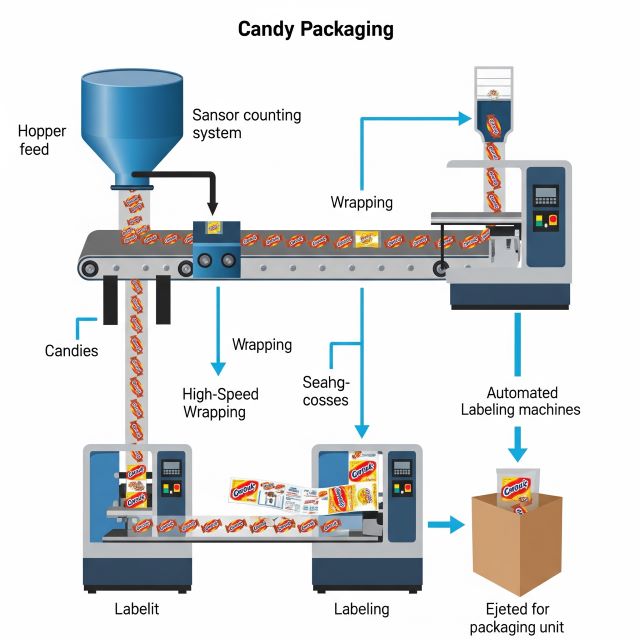

Candy packaging machinery operates through a combination of processes that work together to ensure that each candy is wrapped, counted, sealed, and labeled accurately. Understanding how these processes work can help you identify the best machine for your business.

Feeding: The candy feeding process involves transferring the candies from bulk containers into the packaging machine. This is typically done using hoppers, chutes, or conveyor belts. For candies of similar shapes, vibratory feeders are often used to maintain an even flow of product into the machine.

Counting: Accurate counting is critical to ensure that the correct number of candies are packaged in each container. Depending on the machine type, counting can be done using mechanical counters, photoelectric sensors, or weight-based systems.

Wrapping and Sealing: The wrapping process involves encasing the candy in a film or wrapper to protect it and maintain its freshness. Plastic films, aluminum foil, or composite materials are typically used for wrapping. Once the candy is placed inside the wrapper, the machine seals the package by applying heat or pressure, ensuring the candy is securely enclosed.

Labeling: Labeling machines automatically apply labels to the finished product, which can include important details such as the brand name, ingredients, expiration date, and barcodes. Proper labeling is crucial for product identification and marketing.

Ejection and Integration: After the candy is packaged and labeled, the finished products are ejected from the machine and sent to the next stage of production. This might include secondary packaging (such as placing candy packages into boxes or cartons) or storage.

Several types of candy packaging machines are available, each suited to different packaging formats and candy types:

Flow Wrappers: These are ideal for individually wrapped candies. Flow wrappers are versatile and can handle a variety of candy types, including chocolates, toffees, and gums.

Pre-Made Pouch Packing Machines: These machines work with pre-manufactured pouches and are great for packing candies in bulk. They can handle multiple pouch sizes, offering flexibility in packaging different candy types.

High-Speed Pouch Packaging Machines: Designed for packing multiple candies in a single pouch, these machines are ideal for high-volume production.

Cut and Twist Wrapping Machines: These machines twist the ends of the wrapping material to enclose the candies. They are commonly used for hard candies that require twisted wrappers.

Candy Sorting Machines: These machines sort candies by size, color, or type before packaging, ensuring uniformity and preventing mixed products in the packaging process.

One of the key benefits of candy packaging machines is their ability to increase production efficiency. Automation allows the machine to operate continuously, without the need for frequent breaks or downtime. This significantly speeds up the packaging process, allowing your business to handle large production volumes while maintaining consistent quality.

The packaging of candies is critical to preserving their freshness and quality. Candy packaging machines provide an airtight seal that protects candies from environmental factors like moisture, air, and contaminants. Whether you are packaging chocolates, gummies, or hard candies, the machinery ensures that the product is safe, fresh, and properly sealed.

Proper packaging plays a key role in extending the shelf life of candy products. By using the correct packaging materials—such as aluminum foil or plastic films—the candy is kept fresh by preventing moisture from entering the packaging. This is particularly important for products like chocolates, which can melt or become stale without proper protection.

Packaging is often the first thing a consumer notices about a product. Professionally designed packaging, coupled with accurate labeling, enhances the visual appeal of your candies, attracting more customers. The use of stand-up pouches, rigid containers, or cartons can provide your products with a premium appearance, increasing consumer trust and driving sales.

Choosing the right candy packaging machine involves selecting the proper packaging format and materials. Here are the most common packaging materials and styles used in the candy industry:

Plastic Films: The most common material used for candy packaging, plastic films offer flexibility and moisture resistance. These films come in various types, including polyethylene (PE) and polypropylene (PP), both of which provide effective barrier protection.

Aluminum Foil: This material offers excellent protection against air, moisture, and light. It is often used for premium products, such as chocolates and gourmet candies, to ensure freshness and longevity.

Composite Materials: These are multilayer materials that combine different substances, such as plastic and foil, to provide enhanced protection and strength. Composite materials are often used for products requiring a higher level of barrier properties.

Cardboard Boxes: Commonly used for bulk packaging, cardboard boxes are lightweight and provide safe transportation for candy products. They are often used for packaging multiple items together.

Boxes and Cartons: These packaging options are ideal for bulk packaging and are typically used to package a large number of candy units. Cardboard boxes are lightweight, customizable, and protect the candies during transport.

Pouches: Stand-up pouches, stick bags, and flow-wrap bags are popular for single-serving candy packages. These pouches are convenient for consumers and often feature resealable closures.

Rigid Containers: Bottles, jars, and cans are used for premium candy products. These containers are durable and provide added protection, making them ideal for gourmet candies or products intended for long-term storage.

When selecting a candy packaging machine, several factors must be considered to ensure you choose the right equipment for your business.

Different candy types require different packaging methods. For example, hard candies, chocolates, and gummies have distinct shapes and consistencies, so they may require different machines to ensure proper packaging. Be sure to choose a machine that can handle your specific candy type.

The speed and capacity of your candy packaging machine will depend on the volume of production. High-speed machines are ideal for large-scale operations, while slower, more affordable models may be suitable for smaller businesses.

Ensure the machine you select is compatible with your desired packaging material and format. If you plan to use pre-made pouches, make sure the machine can handle that style, as some machines are designed specifically for pre-manufactured bags.

Since candy packaging machines are used for food products, it’s crucial that the machine adheres to hygiene standards and complies with food safety regulations. Machines should be easy to clean and maintain, reducing the risk of contamination.

While initial costs can be significant, the long-term benefits of automation should be considered. Factor in both the upfront investment and ongoing maintenance costs when choosing the right machine for your business.

To ensure that your candy packaging machine remains in optimal condition, regular cleaning and maintenance are essential.

At the end of each production day or between runs, clean the machine’s surfaces, including conveyor belts, hoppers, and product-contact areas. This will prevent contamination and buildup of debris, ensuring that your machine runs efficiently.

At least once a month, conduct a deep cleaning of the machine. This includes disassembling parts like nozzles, dies, and sensors for thorough cleaning. Periodic deep cleaning is essential for preventing clogs and ensuring that the machine operates smoothly.

Regularly inspect and maintain components such as belts, motors, and gears. Lubricate moving parts and replace any worn-out components before they cause downtime.

Regular calibration and alignment checks are necessary to prevent misalignments, which can lead to product defects and machine breakdowns. Keeping the machine aligned will ensure accurate packaging.

Wrapper tears can result from improper tension settings or worn-out parts. Regular maintenance and timely replacement of parts can prevent these issues, ensuring that the wrapping material remains intact.

Miscounts and overfilling are common issues that can arise during candy packaging. To avoid this, ensure that the counting mechanisms are regularly maintained and calibrated to achieve accurate counts.

Unplanned downtime can be costly. Regular maintenance and the availability of spare parts can reduce the likelihood of machine breakdowns, keeping your production line running smoothly.

Integrating different stages of the packaging process—such as feeding, counting, wrapping, and labeling—can create a seamless production line, improving overall efficiency.

By automating the entire packaging process, you can operate your production line 24/7 with minimal human intervention, increasing productivity while reducing labor costs.

Choosing the right materials and minimizing excess can save costs and reduce waste. Implementing optimal controls and using automated cutters can also help reduce material waste.

Adjust the line speeds to ensure each stage of production flows smoothly. By monitoring and enhancing the efficiency of each step, you can optimize productivity.

The integration of smart sensors, AI, and automated quality control systems is revolutionizing candy packaging. These technologies increase efficiency, reduce errors, and ensure high-quality packaging.

With increasing consumer demand for sustainability, the candy packaging industry is moving toward eco-friendly options. Packaging materials like biodegradable films and recyclable materials are becoming more prevalent, reducing the environmental impact of candy packaging.

Personalized and creative packaging solutions are gaining popularity. With the ability to print custom designs and labels, candy manufacturers can create unique and appealing packaging that stands out on store shelves.

Q1: What types of candy packaging machines are available?

There are various types, including flow wrappers, pre-made pouch packing machines, and cut and twist wrapping machines, each suitable for different candy types and packaging formats.

Q2: How can candy packaging machinery reduce product waste?

By ensuring accurate counting, precise filling, and minimal overfilling, packaging machines reduce product waste and improve efficiency.

Q3: What materials are best for packaging candy?

Plastic films, aluminum foil, and composite materials are commonly used due to their flexibility, moisture resistance, and ability to extend shelf life.

Q4: How much does a candy packaging machine cost?

The cost varies depending on the machine’s speed, features, and capacity. Smaller machines may cost a few thousand dollars, while larger systems can cost tens of thousands.

Q5: How do I maintain my candy packaging machine?

Regular cleaning, lubrication, and part replacement are essential to maintain your machine’s performance and longevity.

Selecting the right candy packaging machine is crucial for your business’s efficiency, product quality, and long-term success. By considering factors such as candy types, production volume, and packaging needs, you can choose a machine that meets your specific requirements. Regular maintenance and adopting the latest trends in automation and sustainability can further enhance the performance and cost-effectiveness of your production process.

The Ultimate Guide To Filling Machines for Cosmetics

The Ultimate Guide To Pouch Packing Machines:Types,Benefits,And Buying Tips

Cookie Packaging Machine – The Ultimate Guide to Choosing the Right Solution