T: +86-189-2891-8174

E: wechupack@yeah.net

E: wechupack@yeah.net

104 The Second Building, No.43 Haichong Road, Shiqi Town,Panyu District, Guangzhou City, China

Views: 0 Author: Site Editor Publish Time: 2025-06-12 Origin: Site

Blister packaging is a widely used method in packaging industries worldwide, providing protection for various products, particularly in pharmaceuticals, medical devices, and consumer goods. It involves a machine designed to form cavities or pockets from plastic, fill them with products, and seal them to prevent tampering, contamination, and degradation. A Blister Packaging Machine is an essential piece of equipment in this process, ensuring product integrity, safety, and efficiency. In this comprehensive guide, we will explore the types of blister packaging machines, their working processes, key features to consider when choosing one, and their applications in different industries. Additionally, we will examine some innovations in blister packaging and provide insights into optimizing your machine's performance.

A Blister Packaging Machine is a device used to create blister packs, which are a type of pre-formed plastic packaging. These machines form cavities in plastic films, insert products (such as tablets, capsules, toys, or medical instruments), and then seal the cavity with a backing material like aluminum foil or paperboard. This process offers excellent protection against moisture, tampering, and contaminants.

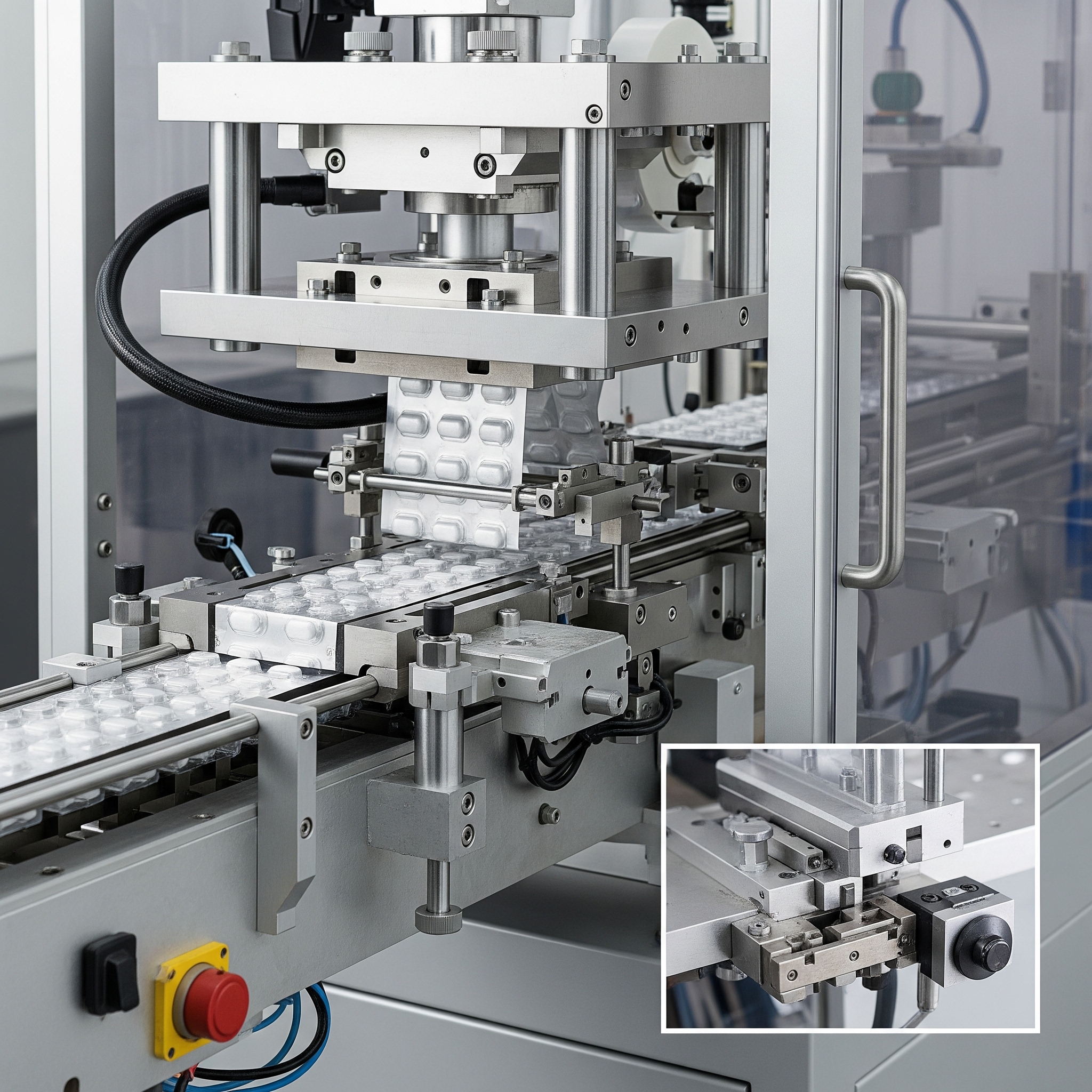

Blister packaging machines are crucial for industries where product protection is paramount, especially in the pharmaceutical and medical device sectors. The machine's design ensures that each product is securely packaged, preventing damage during transportation or storage. Furthermore, the process of creating blister packs can be done quickly and efficiently, making it a preferred choice for manufacturers worldwide.

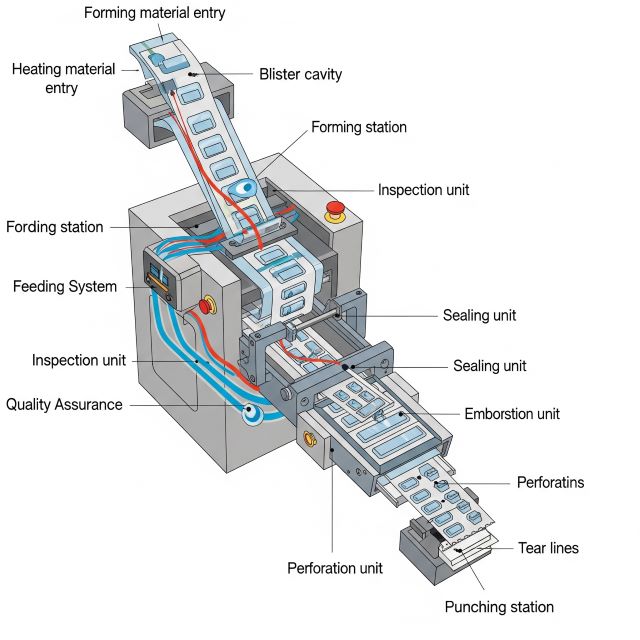

A Blister Packaging Machine operates in a form-fill-seal process, where it forms, fills, and seals the blister packs in one continuous cycle. The machine has several key components that work together to ensure the packaging is secure and efficient.

Forming Material: This is the base material used to create the blister pockets. Common materials include PVC, PVDC, PP, and cold-form aluminum.

Heating: The forming material is heated until it becomes soft and pliable.

Forming: The heated material is shaped into cavities using molds and pressure.

Feeding: The products (such as pills, capsules, or small consumer goods) are fed into the formed cavities.

Inspection: This step ensures the correct positioning of products and checks for defects.

Sealing: A lidding material, such as aluminum foil or plastic, is applied over the blister cavities and sealed to ensure the products are securely contained.

Embossing: A code, batch number, or expiration date is imprinted on the lidding material.

Perforation: Some blister packs include perforations between pockets for easy separation.

Punching: The final step involves punching out the individual blisters from the sheet.

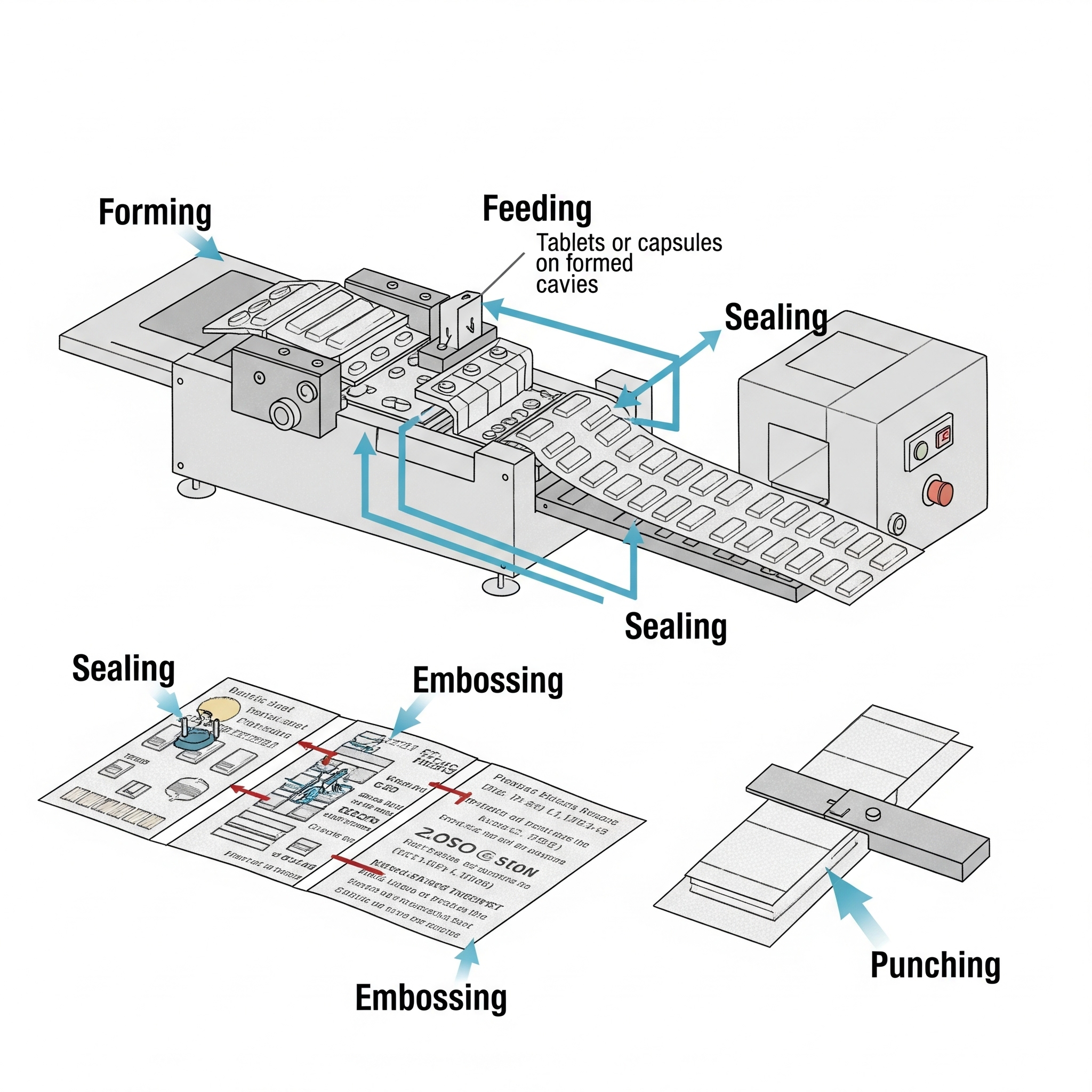

Forming: Plastic film is heated and formed into pockets.

Feeding: Products are placed in the pockets.

Sealing: The pockets are sealed with a lidding material.

Embossing: Batch details or dates are added.

Punching: The individual blisters are separated.

This process ensures that each blister pack is airtight, tamper-evident, and resistant to external factors such as moisture and light.

There are two primary types of Blister Packaging Machines: Platen-style and Rotary-style. Each type has its own set of advantages and is suited for different production needs.

A Platen-style Blister Packaging Machine is an intermittent motion machine that uses upper and lower seal molds that close and separate repeatedly. This type of machine is ideal for producing blister packs with larger cavities or complex shapes. It offers excellent flexibility in mold exchange, making it suitable for manufacturers that produce a variety of products, such as ampoules, vials, or tablets of different sizes.

Flexibility for various product shapes.

Suitable for large blister cavities.

Ideal for low to medium production volumes.

Slower production speed compared to rotary machines.

Requires more space for operation.

A Rotary-style Blister Packaging Machine operates with continuous motion, where the blister material moves around a rotary drum. This type of machine is faster than platen-style machines and is suitable for high-volume production. It is primarily used for products that require simpler blister cavity shapes, such as standard tablets or capsules.

Faster production speed.

Smaller footprint due to continuous motion.

Higher production efficiency for simpler products.

Less flexible in terms of mold exchange.

Not ideal for large or complex product shapes.

When choosing between platen-style and rotary-style machines, consider factors such as:

Production volume: Rotary machines are better for high-volume production, while platen machines are more suitable for low to medium volumes with varying product shapes.

Product complexity: Platen machines offer more flexibility for complex product designs, while rotary machines work best for simpler products.

Selecting the right Blister Packaging Machine depends on several factors. Here are the key features to consider:

The speed of the machine is crucial for determining how quickly your production line can operate. Rotary machines typically have faster speeds, but platen machines offer greater flexibility for handling different types of products.

Blister packaging machines can handle a variety of materials, including PVC, PVDC, PP, and cold-form aluminum. The material you choose will depend on the type of product you're packaging and the required barrier properties.

If your production involves various product shapes and sizes, choose a machine that allows easy mold exchange. Platen-style machines excel in this area, offering more flexibility than rotary-style machines.

For pharmaceuticals and medical devices, it is essential that your machine meets regulatory requirements, such as those outlined by the FDA, EU guidelines, and ISO standards. Ensure the machine is capable of handling tamper-evident packaging and maintaining product integrity.

Modern Blister Packaging Machines often include inspection systems to detect defects such as missing products, broken tablets, or incorrect packaging. These systems help ensure quality control and reduce the likelihood of packaging failures.

The choice of material used in blister packaging directly affects the protection, cost, and appearance of the blister packs. Below are some common materials used:

Advantages: Low cost, easy to thermoform.

Disadvantages: Poor barrier properties against moisture and oxygen.

Best for: Simple products that do not require extended shelf life.

Advantages: Excellent moisture and oxygen barrier.

Disadvantages: Expensive.

Best for: Pharmaceutical packaging where long shelf life is critical.

Advantages: Good barrier properties, lightweight, recyclable.

Disadvantages: Expensive compared to PVC.

Best for: Eco-friendly packaging and products requiring good mechanical strength.

Advantages: Superior barrier properties, extends shelf life.

Disadvantages: Slower production speed, less transparent.

Best for: High-end pharmaceutical packaging requiring extended product shelf life.

Each material has its benefits and limitations, so it is crucial to choose the right material based on the product's requirements.

In the pharmaceutical industry, Blister Packaging Machines are used for packaging unit-dose products such as tablets, capsules, and lozenges. The blister pack provides an effective barrier to moisture, air, and light, ensuring the integrity and shelf life of the products. Additionally, blister packs can be used to create compliance packs that help patients track their medication intake.

Medical devices, such as sterile instruments and syringes, also benefit from blister packaging. These packs provide tamper-evident sealing and can be designed to meet strict sterilization requirements.

Blister Packaging Machines are widely used in the packaging of consumer goods, including toys, hardware, and electronics. The clear plastic allows consumers to view the product before purchase, while the sealed blister provides protection against damage and theft.

The food and cosmetics industries use blister packaging to preserve products and ensure freshness. Blister packs can be designed to provide a protective seal that extends the shelf life of food products, while also offering ease of use for customers.

Protection: Blister packs provide excellent protection against external elements such as moisture, oxygen, and contaminants.

Tamper-evidence: The sealed design of the blister ensures that products are tamper-proof, providing peace of mind to consumers.

Cost-effectiveness: Blister packaging is a cost-effective solution for packaging small and medium-sized products.

Product Visibility: Clear blister packs allow customers to view the product, aiding in purchase decisions.

Branding and Marketing: Blister packs can be customized with various prints, making them a valuable tool for brand promotion.

While Blister Packaging Machines are efficient, there are several challenges that manufacturers must address:

Certain materials, such as PVC, have limited barrier properties, making them unsuitable for products requiring long shelf lives. Manufacturers may need to consider alternative materials like PVDC or cold-form aluminum to improve protection.

Regular maintenance is required to ensure the Blister Packaging Machine operates smoothly. This includes cleaning the machine, checking for wear and tear, and replacing parts as necessary.

Manufacturers must strike a balance between production speed and flexibility. Rotary-style machines offer higher speed but are less flexible, while Platen-style machines provide greater flexibility but at a slower speed.

The use of plastic materials in blister packaging raises environmental concerns. Manufacturers are increasingly exploring eco-friendly packaging solutions and recyclable materials to address these concerns.

Recent innovations in blister packaging have focused on enhancing efficiency, improving product protection, and reducing environmental impact.

Cold-form foil blisters offer superior protection against moisture and oxygen, extending the shelf life of the product.

Integrating sensors into blister packaging machines allows for real-time monitoring and quality control.

Manufacturers are increasingly focusing on using biodegradable materials and reducing plastic waste in packaging processes.

The Blister Packaging Machine is an indispensable tool in the packaging industry, providing an efficient, cost-effective, and protective method for packaging a wide range of products. By understanding the different types of machines, their processes, and the factors to consider when choosing one, manufacturers can ensure that their packaging meets the highest standards of quality, compliance, and efficiency.

When selecting a Blister Packaging Machine, consider factors such as machine speed, material compatibility, and flexibility. As innovation continues to shape the future of packaging, manufacturers must also keep an eye on emerging trends such as smart packaging and eco-friendly solutions to stay ahead in a competitive market.

With the right Blister Packaging Machine, companies can enhance their production processes, improve product protection, and meet consumer demand for high-quality, secure, and environmentally conscious packaging.

What is the difference between a platen-style and rotary-style blister packaging machine?

Platen-style machines use intermittent motion, offering flexibility for complex products. Rotary-style machines are faster with continuous motion, ideal for high-volume production of simpler items.

What materials are used in blister packaging?

Common materials include PVC, PVDC, PP, and cold-form aluminum, each providing different levels of moisture and oxygen barrier properties.

How do I choose the right blister packaging machine for my production needs?

Consider factors like production volume, product complexity, machine speed, and flexibility for mold exchanges.

Can blister packaging machines handle small and large batch productions?

Yes, machines can be adapted for various batch sizes, depending on the type and design.

How can I ensure the quality of my blister packs?

Use inspection systems before sealing and after punching to detect defects and ensure quality control.