Ukupakishwa kwamakhemikhali kudlala indima ebaluleke kakhulu kwiFreeccycle yemikhiqizo yezokwelapha. Ngokungafani nokupakisha kwezinye izimboni, ukufakwa kwemithi kumele kuhlangatshezwane nezidingo ezingejwayelekile eziphathelene nokuqina, ukunemba kwe-dosing, ubufakazi obuphazamisayo, kanye nokuhambisana nokulawula. Lezi zimfuno zibucayi hhayi ukuvikela ubuqotho kanye nokusebenza kahle kwezidakamizwa kodwa futhi nokuqinisekisa ukuphepha kweziguli nokwethenjwa emidlalweni yemithi.

Njengoba amazinga ezempilo emhlabeni jikelele avela futhi izinhlaka zokulawula ziba ngcono, abakhiqizi bezemithi baphendukela ekuthuthukisweni imishini yokufaka ukufeza lezi zinselelo. Ukusuka emishini yokupakisha ebheke mpo ngezinhlelo ezihlanganisiwe zokufaka izixazululo zokupakisha kanye nemishini yakhelwe ngokuqinile ngokuya ngemithetho ye-GMP (ukukhiqiza okuhle), ubuchwepheshe bokufaka okulungile bungaba ngumshayeli wegeyimu ekuqinisekisweni kwekhwalithi kanye nokusebenza kahle kwekhwalithi.

Izidingo ezibucayi zokupakishwa kwemithi

Ukupakishwa kwamakhemikhali akusho nje ngokufaka umkhiqizo; Kusebenza imisebenzi eminingi ebucayi, kufaka phakathi ukuvikelwa, ukunemba komthamo, ukulandelela kanye nokuphepha kweziguli. Ake sihlukane ngalezi zinto ezibalulekile ngokuningiliziwe.

1. Ukuqina kanye nokulawulwa kokungcola

Imikhiqizo yezemithi - ikakhulukazi ukujova, ama-powders, kanye nama-capsule-kumele kufakwe ngendlela egcina inzalo futhi ivimbela ukungcoliswa kwamagciwane, uthule, nezinye izinto zakwamanye amazwe. Imishini yokupakisha esetshenziswe emkhakheni wezemithi kaningi isebenza ezindaweni ezilawulwa yindawo yokuhlanza ukunciphisa ubungozi bokungcola.

Imishini ngokwayo kumele yenziwe ngensimbi engenasici noma kwezinye izinto ezingezona ezonakele ezingamelana nokuhlanza okuphindaphindiwe kanye nemijikelezo yokuhlanza inzalo. Ngokwengeziwe, imigqa eminingi yokufaka ifaka ama-HEPA Filtration Systems, ukuphatha umkhiqizo ezenzakalelayo, kanye nezindawo ezifakiwe ezifakiwe ukuze uqhubeke nokuqinisekisa inzalo yomkhiqizo.

2. Ukubekwa uphawu kwe-Hermetic kanye nobufakazi obuphazamisayo

Eminye yemisebenzi eyinhloko yokupakishwa kwemithi ukuhlinzeka ngophawu oluholayo oluvikela ngokumelene nomswakama, umoya-mpilo, nokukhanya, okungalimaza umkhiqizo. Ukwehluleka okupakisha okufana nokuvuza noma izibuko ezibuthakathaka kungahlehlisa ukusebenza kwezidakamizwa noma ukuphepha.

Ngaphezu kwalokho, izici ze-tamper-eziveli njengamaphakethe we-blister avaliwe, amateyipu okuphepha, noma ukugoqwa okuncipha kubalulekile ukuvikela ukufinyelela okungagunyaziwe kanye nokuqinisekisa abathengi kanye nemizimba yokulawula umkhiqizo kuphephile futhi kungafakwanga.

I-3. Umthamo oqondile nokulawulwa kwesisindo

Ukuqinisekisa ukuthi wonke iphakheji iqukethe inani elifanelekile lemithi liyimfuneko engaxoxiswanga emikhakheni. Ukugcwala kwemiphumela ekungcoleni komkhiqizo kanye nezindleko ezandisiwe, ngenkathi i-underfing ingabeka engcupheni impilo yeziguli futhi imeme unswinyo lokulawula.

Ukubhekana nalokhu, imishini yokupakisha ivame ukuhlangana nezinhlelo zokuqonda noma izindlela zokuthambisa ezilinganisa ngokuzenzakalelayo ama-powders, ama-granules, noma uketshezi ngaphambi kokugcwalisa iphakheji. Lezi zinhlelo zinikeza amandla okubheka ku-inthanethi kanye namakhono okulungiswa, okuvumela abakhiqizi ukuthi balondoloze ukubekezelelana okuqinile kwithango.

4. I-batch coding kanye nokulandelela

Ukulandelela kubalulekile ku-Pharmaceuticals. Iphakethe ngalinye kufanele libonise imininingwane ecacile efana nenombolo ye-batch, usuku lokukhiqiza, usuku lokuphelelwa yisikhathi, futhi kwesinye isikhathi izinombolo noma ama-barcode wokulandela umkhondo nokukhumbula ukuphathwa kokulandela nokukhumbula ukuphathwa.

Imishini yokupakisha ifakwe amaphrinta we-inkjet, amakhodi we-laser, noma ama-afayili abafakizicelo abaphrinta le datha ebucayi ezintweni zokufaka ngesikhathi sokukhiqiza ngesikhathi sokukhiqiza. Izinhlelo ezihlanganisiwe zokulawulwa kwedatha zingaqinisekisa ukunemba nokuhlala kwaphakade kwalezo zimpawu zokuhambisana nemihlahlandlela yokulawula.

Imishini yokupakisha mpo nezinhlelo ezinesisindo sezidakamizwa ze-granular and oluyimpuphu

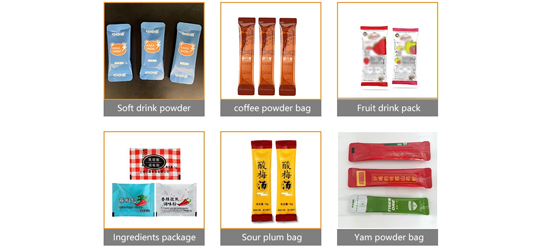

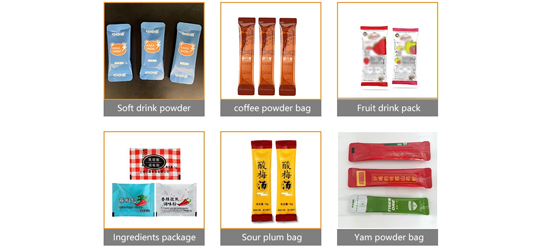

Ngemikhiqizo yezemithi nge-powder noma ifomu le-granular - njengemithi elwa namagciwane, izithasiselo zokudla okunempilo, noma imishini yefomu le-capsule-mpo gcwalisa uphawu (ama-Vffs) abhangqiwe nezinhlelo ezithuthukile ezinesisindo zinikeza isixazululo esifanelekile sokufaka.

Imishini yokupakisha mpo isebenza kanjani

Imishini yokupakisha mpo Sebenzisa umqulu wefilimu eguqukayo eyenziwe ngeshubhu elizungeze i-nozzle yokugcwalisa. Umshini ubeka uphawu lwe-tube mpo ukudala isikhwama, ugcwalisa umkhiqizo usuka phezulu, bese ulifaka uphawu ngokuvundlile ukuvala iphakheji.

Lo mklamo uvumela ukuhanjiswa okuqhubekayo, okunesivinini esikhulu ngesinyathelo esincane sonyawo, okwenza kube lula ngezindawo ezihlanzekile.

Ukuhlanganiswa kokunemba okuhlole izinhlelo

Imigqa ye-veffs yemithi evame ukuhlanganisa amakhanda amakhanda amaningi noma ama-feeders alahlekile aqinisekisa ukuthi iphakethe ngalinye liqukethe umthamo oqondile. Lezi zinesisindo ngokushesha zikala umkhiqizo ngaphambi kokuthi zigcwaliswe, zinikeza ukulawula okuqhubekayo kwesikhathi sangempela kanye nokunciphisa umkhawulo womkhiqizo.

Ukuzenzakalelayo okunjalo kunciphisa iphutha labantu futhi kuqinisekisa ukuthi wonke iphakethe lihambisana nemikhawulo eqinile yokulawula umthamo, ekugcineni uvikele ukuphepha kweziguli.

Izinzuzo zokupakishwa kwemithi

I-Sanitary Design: Imishini eyakhiwe ngensimbi engama-316l yensimbi engenasici ngenhlanzeko ehambisanayo, i-CIP (ihlanzekile) indawo ehambisanayo yokuhlanzeka futhi yehlise ubungozi bokungcola.

Zokupakisha Eziguqukayo Izinketho

Ukukhubazeka kanye nesivinini: Le mishini isekela ukukhiqizwa okuphezulu kwevolumu ngaphandle kokuyekethisa ngekhwalithi yokufaka, ukusiza izinkampani ezenza imithi zihlangabezana nezidingo ezikhulayo kahle.

Izicelo ezijwayelekile

Ama-powders ama-antibiotic nama-caplule

Izithasiselo zokudla okunempilo

Imithi yokuphefumula eyimpuphu

Amaphakethe we-palders e-counter

Imishini yokupakisha ye-Vacuum yemithi ebucayi - imithi yaseChina yendabuko

Imishini yokupakisha ye-Vacuum isiphenduke imali enkulu yokufaka amakhambi okuma komswakama, kufaka phakathi nemithi ye-herbal, umuthi wendabuko waseChinese (i-TCM), nezinye izindlela ezibucayi zezidakamizwa.

Kuyini ukupakishwa kwe-vacuum?

Ukupakishwa kwe-Vacuum kukhipha umoya ovela kwiphakheji ngaphambi kokubekwa uphawu, ukunciphisa kakhulu ubukhona be-oxygen kanye nomswakama - izinto ezimbili ezibalulekile ezisheshisa ukuwohloka kwemithi kanye nokukhula kwe-microbial.

Le nqubo ithuthukisa impilo yaseshalofini futhi ilondoloze i-potency, iphunga, kanye nokuphepha komkhiqizo.

Izicelo emikhiqizweni yezemithi kanye nekhambi

Imithi ye-Herbal, ama-powders, izimpande, kanye nama-caplule avame ukuqukatha amakhompiyutha asebenzayo noma athambile awohloka kalula ukuvezwa komswakama noma ukuvezwa komoya-mpilo. Ukuhanjiswa kwe-vacuum kugcina lezi zinto ezibalulekile, ukugcina ikhwalithi yomkhiqizo kulo lonke ukugcinwa nokuhamba.

Izinzuzo zokupakishwa kwe-vacuum

Inwebisa impilo yeshelufu: ngokususa umoya, ukupakishwa kwe-vacuum ukubambezela i-oxidation kanye nokuphangwa okubangelwa umswakama.

Kuthuthukisa ukuphepha kwe-microbial: kwakha izimo ze-anaerobic ezingathandeki kumagciwane amaningi.

Ukuhlanganiswa okuhlangene: Yehlisa ivolumu, ukonga ukugcina nezindleko zokuthumela.

Umbono wabathengi othuthukisiwe: Imikhiqizo evalwe uphawu ye-vacuum iyabonakala njengekhwalithi ephezulu nekhwalithi ephezulu.

Design Izici zemishini yokupakisha ye-geamceutical vacuum

Yakhelwe ngensimbi engenasici, ukuhlanzeka komhlangano kanye namazinga wokuhlanza inzalo.

Amazinga we-vacuum aguqukayo ukuphatha imithi ehlanzekile ngaphandle komonakalo.

Ongakukhetha i-nitrogen idonsela ukuvikela izithako ezibucayi ze-oksijini.

Ukuhlanganiswa nemigqa yokukhiqiza ehlanzekile ukuqinisekisa ukutholwa kwe-GMP.

Ukuklama imishini yokufaka ehlangabezana namazinga we-GMP

Imithethonqubo yokukhiqiza enhle (GMP) ibalulekile ekukhiqizweni kwemithi ukuqinisekisa ikhwalithi yomkhiqizo, ukuphepha, kanye nokusebenza ngempumelelo. Imishini yokupakisha kumele ibe nenhloso noma iguqulwe ukuze ivumelane nalezi zindinganiso ezinzima.

Kungani kutholwa izindaba ze-GMP

Imihlahlandlela ye-GMP iqondisa yonke inqubo yokukhiqiza, kufaka phakathi ukupakishwa, ukuqinisekisa ikhwalithi engaguquki futhi yehlisa ubungozi bokungcola. Ukungalandeli kungaholela ekukhumbuleni okubizayo, unswinyo lokulawula nokulahleka kwethemba lokuthengiselana.

Imigomo yokuqamba ye-GMP yemishini yokupakisha

Izinto zokwakha: Sebenzisa izinto ezivunyiwe ze-FDA njengensimbi engu-316l yensimbi engenacala emelana nokugqwala nokubekezelelana.

Ukuhlanzeka: Imishini ifaka izindawo ezibushelelezi, amakhona ayindilinga, kanye nemilondo emincane ukuvikela ukwakhiwa kwe-microbial futhi kube lula ukuhlanza.

I-automation: Yehlisa ukuxhumana nabantu ngemikhiqizo, ukunciphisa ubungozi bokungcola.

Izindawo ezilawulwayo: Imigqa yokupakisha ivame ukusebenza ngaphakathi kwamagumbi okuhlanza ama-iso, asekelwa yi-laminar airflow hoods.

Ukuthembeka kwedatha: Imishini isekela amarekhodi we-elekthronikhi ama-batch kanye nemibhalo ezenzakalelayo yokucwaningwa kwamabhuku okulawulwa.

Izinhlelo eziqinisekisiwe: Imishini yokufaka i-IQ / OQ / PQ (ukufakwa, okusebenzayo, iziqu zemfanelo zokusebenza) ukuze uqinisekise ukuhambisana.

Izinzuzo zemishini ye-GMP-ehambisanayo

Ukuvunyelwa Ukuvunyelwa Ukuvunyelwa

Ukuphepha Okuthuthukisiwe Komkhiqizo Nokuvumelana

Ukuncishiswa ekungcoleni-ukungcoliswa futhi kukhumbula

Ukusebenza kahle kokukhiqizwa okuthuthukisiwe ngokunciphiswa kwesikhathi

Ukugcina

Ukupakishwa kwemithi kudinga amazinga aphezulu okunemba, inzalo kanye nokuhambisana nokulawula ukuqinisekisa ukuphepha kweziguli kanye nobuqotho bomkhiqizo. Imishini yokupakisha ethuthukile evelele enezinhlelo ezihlanganisiwe ezinesisindo inikeza izixazululo ezinembile, ezisebenzayo zamaphondoji kanye nama-granule, ngenkathi ukupakishwa kwe-vacuum kuhlinzeka ngokuvikelwa okubalulekile kwemithi ebucayi-umswakama, kufaka phakathi imikhiqizo yendabuko yamakhambi. Ngokusobala, imishini eyenzelwe ukuhlangabezana namazinga ajwayelekile we-GMP Amazinga asekela abakhiqizi ekugcinweni kwekhwalithi nokuthembela kokulawula.

Izinkampani ezenzakade amakhambi zifuna izixazululo ezithembekile zokufaka, IGuangzhou Tengzhuo Paking Equiced Co, Ltd. Inikeza uhla oluphelele lwemishini elungiselelwe kulezi zidingo eziqondile. Ubuchwepheshe bethu ekwakheni ama-GMP-ahambisana ne-GMP-aclessiant, imishini yokufaka esebenza kahle ingasiza ekusakazeni inqubo yakho yokukhiqiza ngenkathi uvikela ikhwalithi yomkhiqizo. Ukuze ufunde kabanzi ngokuthi uhlelo lwethu olusebenzayo Imishini yokupakisha ingaphakamisela ukukhiqiza okwemikhandlu, sincoma kakhulu ukuvakashela iwebhusayithi yethu ku www.weechumachine.com noma ukuxhumana nethimba lethu ngqo ngokubonisana nokusekelwa okwenziwe ngezifiso. Ukutshala imali kubuchwepheshe bokufaka okulungile kubalulekile ekuqhubekeni nokuncintisana nokuhambisana nomkhakha wanamuhla wemithi.