Ukusebenza kahle okuthuthukisiwe:

Umshini wokuvalwa uphawu kweCarton, kufaka phakathi imishini ye-othomathikhi yeteyiphu kanye nabathengisi be-carton, bangathuthukisa kakhulu ukusebenza kahle kokukhiqiza ngokufaka indawo yokufaka incwadi. Le automation ivumela isivinini sokuvalwa kokushesha kanye nokucaciswa okuguqukayo, ukwenza kahle umugqa wokukhiqiza wokupakisha.

Ukuqina Kwabasebenzi Okuncishisiwe:

Ngokusebenzisa ama-sealers we-othomathikhi we-carton, ubunzima bomzimba kwabasebenzi buncishisiwe. Le mishini iqeda ukungakhululeki nokukhathala okuhlotshaniswa nomsebenzi wezandla ophindaphindwayo, okuholela ekusebenzeni okukhiqizayo kakhulu.

Izindleko zokonga kwabasebenzi:

Ukutshala imali emishini yokuvalwa uphawu kwe-carton kuholele ekulondolozeni okukhulu kwezindleko zabasebenzi ngokuhamba kwesikhathi. Lezi zinhlelo ezenzakalelayo zibonisa ukuthi zithembeke kakhulu futhi zezomnotho kunokusebenza ngesandla, ngezindleko zokulungiswa okuphansi, zibenze ukuba zitshale imali ende yesikhathi eside.

Ukuzivumelanisa nezimo okuqinile:

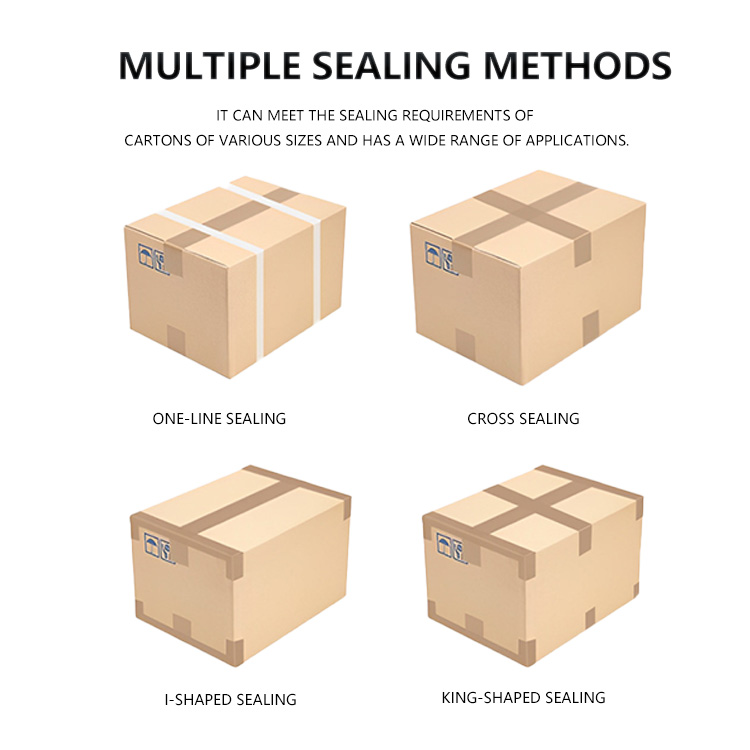

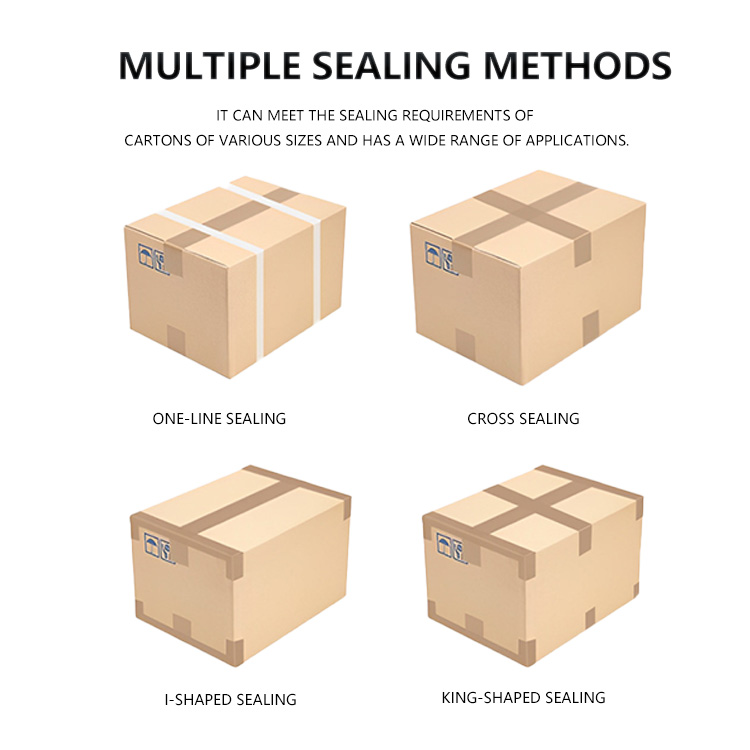

Ama-carton sealers ne-othomathikhi Imishini yokuvalwa uphawu kwebhokisi yenzelwe ukuhlalisa amabhokisi okucaciswa okuhlukahlukene nosayizi. Idizayini yabo eyenziwe ngezifiso ivumela ukuhlanganiswa emigqeni yokukhiqiza ekhona, ukuqinisekisa ukuthi bahlangabezana nezidingo ezihlukile zanoma yikuphi ukusebenza.

Ukuqinisekisa ikhwalithi:

Ikhwalithi yokubopha uphawu enikezwe yi-othomathikhi yebhokisi lokuvalwa uphawu le-automatic iphakeme ngokungaguquki, kunciphisa ubungozi bezimpawu ezikhululekile ezibangelwa yiphutha lomuntu. Lokhu kuthembeka kuqinisekisa ukuthi imikhiqizo ivalwe ngokuphephile, ithuthukisa ubuqotho bokupaka jikelele.

Ukuhlanganiswa okungenamthungo neminye imishini:

Umshini we-Box we-Scriting ungahlanganiswa kalula nemishini yokuvalwa uphawu ye-carton, evumela isisombululo esiphelele sokufaka. Le hlobo lithuthuka ithuthukisa ukuhamba komsebenzi kanye nokusebenza kahle kwenqubo yokupakisha.

Ukusebenza okusebenziseka kalula:

I-carton eningi Imishini yokuvala uphawu ifaka izilawuli ezinembile, ukuzenza kube lula ukusebenzela abasebenzi. Lokhu kulula kunciphisa ijika lokufunda futhi kunika amandla izinguquko ezisheshayo ukufeza izimfuno zokukhiqiza.

Ukukhishwa okukhiqizwayo okuthuthukisiwe:

I-automation enikezwe yimishini yokuvalwa uphawu ye-carton ingakhulisa kakhulu inani lamabhokisi avalwe ngehora ngokuqhathaniswa nezinqubo zezandla, okuholela ezikhathini zokuguqula okusheshayo.

Ngokufundwa, umshini wokuvalwa uphawu weCarton unikeza uhla lwezinzuzo, kufaka phakathi ukusebenza kahle kwezimali, ukuncishiswa kokuqina kwabasebenzi, ukonga izindleko, ukuqinisekiswa kwekhwalithi, ukwenze kube yimpahla ebalulekile yemisebenzi yesimanje yokufaka

I-Logistics and Express Delivery Industry: Emkhakheni wezezimali kanye nokulethwa kwezidingo, amabhokisi angenye yezinto zokufaka ezisetshenziswa kakhulu. Ngokusebenzisa umshini we-carton uvulayo kanye nokwenza uphawu, inqubo yokufaka ingaqedwa ngokushesha, ukonga isikhala sesitoreji kanye nezindleko zesikhathi, kanye nokwenza ngcono umsebenzi ukusebenza kahle.

Imboni ye-Electronics: Umugqa wokukhiqiza wemikhiqizo kagesi udinga ukufakwa okuvama komkhiqizo nokuhamba. Ukusetshenziswa kwe-carton ukuvula kabusha kanye nemishini yokuvala uphawu kungafinyelela imisebenzi eqondile futhi esheshayo yokufaka, ukuvikela ukuphepha kanye nobuqotho bemikhiqizo ngesikhathi sokuhamba.

Imboni yokusebenza yokudla: Izitshalo zokudla zokudla zivame ukufeza ukupakisha izinto ezingavuthiwe noma imikhiqizo eqediwe ngamabhokisi okulawulwa kokugcina nokuhamba. Ngokusebenzisa le mishini, ukuhlanzeka nokuphepha kokudla kungaqinisekiswa futhi isilinganiso sephutha sokusebenza ngesandla singancishiswa.

Ukulungiselela ngaphambi kokuqala

Ngaphambi kokusebenzisa i-othomathikhi ye-carton sealer esebenza ngokugcwele, sicela uqinisekise ukuthi imishini ibekwe ngokuqinile, indawo ezungezile ihlanzekile, futhi akukho okuphazanyiswa imfucumfucu. Bheka ukuthi zonke izingxenye zemishini ziqinile, noma ngabe ibhande elihambisane lenzeke ngentshiseko, nokuthi yini amandla kagesi axhunyiwe ngokujwayelekile. Lungiselela izimpahla ezizovalwa futhi ziqinisekise ukuthi ubukhulu bezimpahla buhambisana ne-carton sealer.

Qala imishini

Xhuma ukunikezwa kwamandla bese uvula ukushintshwa kwamandla kwe-othomathikhi ye-carton sealer. Ngalesi sikhathi, imishini ingena ezweni lokulinda. Lungisa ijubane lebhande lokuhambisa njengoba kudingeka ukufeza izidingo zesivinini esihlukile sokubekwa uphawu se-carton.

Beka izimpahla

Beka izimpahla ukuze zivalwe ngebhande lokuhambisa ukuqinisekisa ukuthi izimpahla kanye nebhande lokuhambisa liqhubekela phambili ngokuvumelanisa. Ukubekwa kwezimpahla kufanele kugcinwe ukuzinza ukugwema ukunciphisa noma ukuwa ngesikhathi sokuhamba.

Lungisa idivaysi yokubopha uphawu

Lungisa isikhundla samateyipu aphezulu nangaphansi wedivayisi yokubopha uphawu ngokuya ngosayizi wezimpahla nezidingo zokubekwa uphawu. Qinisekisa ukuthi itheyiphu ingalingana ubuso bezimpahla ngokuqinile, futhi igweme ukuqina kakhulu noma okukhulula kakhulu ukudala umphumela ompofu wokubopha uphawu.

Qala ukubekwa uphawu

Lapho izimpahla zingena endaweni yokuvala uphawu, i-othomathikhi ye-automatic sealer izokwenza ngokuzenzakalelayo isenzo sokubekwa uphawu. Idivaysi yokuvala uphawu izonamathela ompompi abangaphezulu nangaphansi ebusweni bezimpahla kanye nokushisa okushisa ngamaphepha ngocingo olufudumele kagesi. Ngemuva kokuqedwa kokushiswa kokushisa, idivaysi igawule ngokuzenzakalelayo ompompi ukuqedela inqubo yokubekwa uphawu.

Qoqa izimpahla ezivaliwe

Izimpahla ezivaliwe zizoqhubeka nokuhamba ngebhande lokuhambisa futhi ekugcineni zikhishwe endaweni ephumayo. Sicela uqoqe izimpahla ezivalwe ngesikhathi ukugwema ukunqwabelana kwesikhathi eside kwimishini