Inzuzo yomkhiqizo

Ukusebenza kahle okuphezulu

Imishini yensimbi, kufaka phakathi imishini yokuhlola yegolide neyesiliva, ingahlola inani elikhulu lemikhiqizo ngokushesha, ithuthukisa kakhulu ukusebenza kahle kokukhiqiza.

Ngezinga eliphakeme le-automation, inqubo yokuhlola idinga ukungenelela kwencwajana encane, eminye imisebenzi yokusakaza kanye nesikhathi sokonga.

Ukutholwa okunembile

Sisebenzisa izinzwa ezithuthukile nobuchwepheshe bokucubungula iziginali, abahlaziyi bensimbi kanye nabahlaziyi bensimbi bangathola ukungcola kwensimbi, okufana nokulandela umkhondo wezinsimbi ezingezinhle nezingezinhle, emikhiqizweni ehlukahlukene. Lokhu kucacisa kuqinisekisa ikhwalithi yomkhiqizo engaguquki kanye nokwethenjwa.

Imishini yokuhlola yensimbi yensimbi ingakwazi ukubona kahle izinhlobo ezithile zensimbi, kufaka phakathi igolide nesiliva, okunikeza imininingwane eningiliziwe kwizakhiwo zensimbi.

Ukuqiniseka

Ezimbonini ezinjengokudla, amakhambi kanye nokupakisha, izitoko zensimbi zidlala indima ebalulekile ekuboneni nasekuqedeni ukungcoliswa kwensimbi ngaphambi kokufika kumthengi. Lokhu kuvimbela izingozi futhi kuqinisekise ukuphepha nempilo yomphakathi ngokuvikela imikhiqizo ekungcolisweni kwensimbi.

Abahloli beGolide kanye nesiliva basiza ekuqinisekiseni ubumsulwa bezinsimbi eziyigugu, behlisa ubungozi bezinkohliso noma izingqinamba zokuphepha kubucwebe kanye nemikhakha yezezimali.

Nezimo futhi eziguquguqukayo

Imishini yokuhlola yensimbi kanye nemishini yokuhlola yensimbi yensimbi yenzelwe ukuphatha imikhiqizo yezimo ezahlukahlukene, osayizi, kanye nezinto zokwakha, zibenze zivumelane nezimboni eziningi, kusuka ekwakheni imishini eyigugu yensimbi.

Basekela izindlela zokuhlola eziningi kanye nezilungiselelo ezenziwe ngezifiso, zibavumela ukuba bahlangabezane namazinga athile embonini nezidingo zokuhlola.

C Ost-Impumelelo Ukusebenza

Ngokushintsha inqubo yensimbi kanye nenqubo yokuhlaziya, le mishini isiza ukunciphisa izindleko zabasebenzi, isuse amaphutha abantu, futhi inciphise umkhiqizo ukhumbula ngenxa yokungcola.

Amadivayisi afana ne-Metal Analyzer kanye nemishini yokuhlola yegolide neyesiliva kuhlinzeka ngemininingwane ephelele, kunciphisa isidingo sokuhlolwa okubizayo, okudla isikhathi.

Lezi zinzuzo zenza imishini yokuhlola insimbi, njengokuthola insimbi, ama-story kanye nesiliva, kanye nabahlaziyi bensimbi, amathuluzi asemqoka embonini ebeka phambili ukusebenza kahle, ukunemba, ukuphepha, kanye nokulawulwa kwekhwalithi.

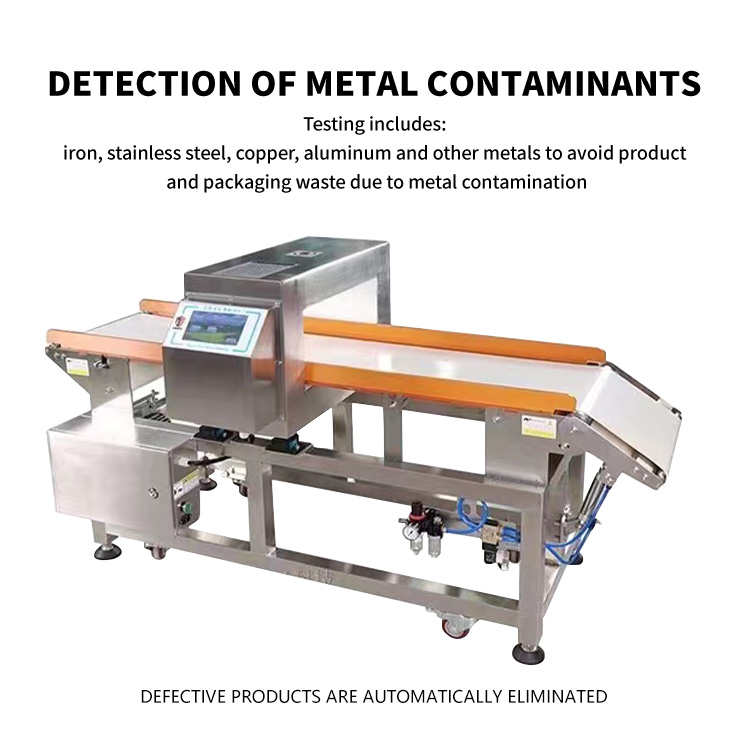

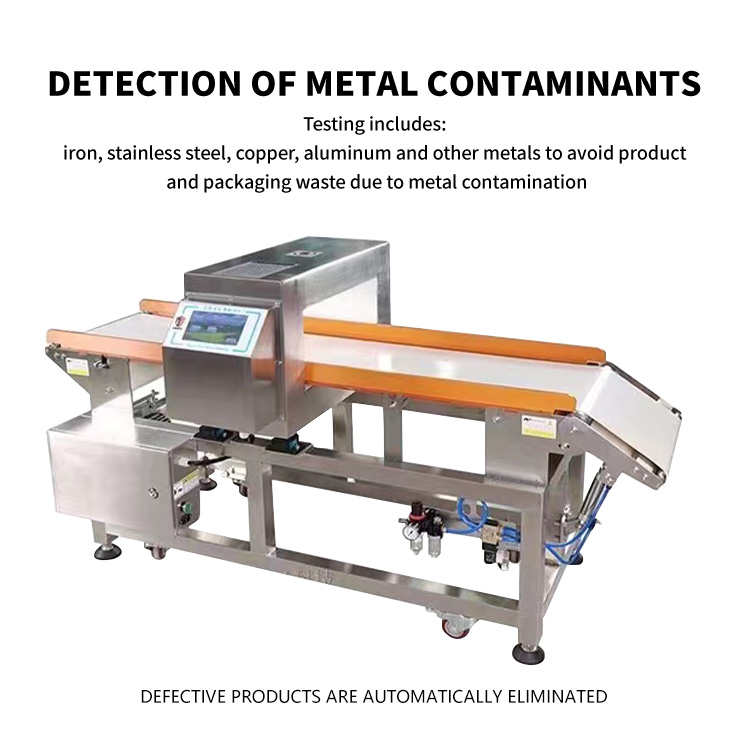

Amapharamitha Ezobuchwepheshe

Isikhombimsebenzisi somshini Womuntu

Usayizi weBelt 1200 * 300 mm

I-Channel Height 100-150 (eyenziwe ngezifiso)

Ukuthola ukunemba kwensimbi engu-0.8, yethusi 1.0, Insimbi Engagqwali 2.0

Ijubane: 20-30 m / min

Indlela yokuthola: I-Electromagnetic Wave

Indlela yokwenqatshwa icindezela induku, ukushaya umoya, yehla, ukuvalwa kwe-alamu

Ukunikezwa kwamandla: 220V, 50 / 60hz

Ukusetshenziswa Komkhiqizo

Imboni yokudla: Ukutholwa kwensimbi kusetshenziswa kabanzi ku- imboni yokudla . Ngokuyinhloko asetshenziselwa ukuthola ama-Metal Metal Atterics Emikhiqizweni ehlukahlukene njengenyama, isikhunta, amaswidi, iziphuzo, imikhiqizo yobisi, imikhiqizo yasemanzini, imikhiqizo yezempilo, izengezo zezempilo. Ukungcola kwensimbi okuxutshwe nokudla kungadala ukulimaza impilo yabantu, ngakho-ke ukusetshenziswa kwezitholi zensimbi kungathola ukungcola kwensimbi ekudleni futhi kusisuse ngokunembile, ngaleyo ndlela kuqinisekiswe ukuphepha nekhwalithi yokudla.

Imboni yezemithi: Embonini yezemithi, abatholi bensimbi basetshenziselwa ikakhulukazi ukuthola okuqukethwe kwensimbi emithini nemikhiqizo yezempilo. Lokhu kusiza ekuqinisekiseni ikhwalithi nokuphepha kwemikhiqizo nokuvimbela ukonakaliswa kokusebenza komkhiqizo noma ukulimaza umzimba womuntu okubangelwa ukungcola kwensimbi.

Imboni yamakhemikhali: Embonini yamakhemikhali, asetshenziselwa ukutholwa kwensimbi ukuthola okuqukethwe kwensimbi kumakhemikhali. Ukungcola kwensimbi kuxutshwe nemikhiqizo yamakhemikhali kungadala ukonakaliswa kokusebenza komkhiqizo futhi kubangele ukulimaza umzimba womuntu. Ngakho-ke, kubaluleke kakhulu ukusebenzisa izitholi zensimbi zokuhlola umkhiqizo.

Imboni ye-metallurgical: Embonini yensimbi, abatholi bensimbi basetshenziselwa ukunquma ukwakheka kwama-batch ahlukene ama-deoxidizers noma ama-ejenti wokubuyisa, kanye nokuhlolwa kwezinto ezahlukahlukene.

Ezokukhiqiza: Embonini yezokukhiqiza, abakwa-Metal Detoms basetshenziselwa ukuhlola imikhiqizo eqediwe noma amasethi aphelele ezingxenye zokuthola ngokushesha izinkinga ezifihliwe ezintweni zensimbi.

Imboni ye-Electronics: Embonini ye-elekthronikhi, abathola insimbi basetshenziselwa ikakhulukazi ukuhlola izingxenye ze-radar ze-microwave, njll.

Umhlahlandlela Wokusebenza Komkhiqizo

Amalungiselelo

Ngaphambi kokusebenzisa umtshina wensimbi, udinga ukulungiselela. Okokuqala, hlola ukuthi uxhumano lwamandla kanye nomjikelezo wemishini kuyinto ejwayelekile. Okwesibili, qiniseka ukuthi izingxenye ezisemqoka zemishini, efana nepuleti ne-sensor, azinakulimala futhi azilimalanga noma zingcolisiwe. Ekugcineni, qiniseka ukuthi indawo yokusebenza kwemishini yomile, inhlanzeko, futhi ingenalo uthuli kanye nemfucumfucu.

Qala imishini

Xhuma amandla womtshina wensimbi, vula ukushintshwa kwamandla kwemishini, futhi imishini iqala.

Lungisa ukuzwela kwemishini

Lungisa ukuzwela kwemishini ngokuya ngezimpawu kanye nezidingo zomkhiqizo okufanele zitholakale. Ngokuvamile, ukukhuphuka kokuzwela, ukunemba okuphezulu kokutholwa, kepha kuzokhulisa futhi isikhathi sokutholwa. Indlela yokushintshanisa ukuzwela imvamisa ukusebenzisa i-Sensitivity additival emishini. Ngokuya ngemishini, i-adjuster ingaba inkinobho ejikelezayo noma ukhiye. Ngokushintsha ukuzwela, imishini ingabona noma ngabe yindaba yakwamanye amazwe kumkhiqizo ngokunembe kakhudlwana.

Beka umkhiqizo

Beka umkhiqizo ukuze ubonakale ebhande lokuhambisa umtshina wensimbi futhi uqinisekise ukuthi umkhiqizo udlula ngokuphelele endaweni yepuleti yokutholwa. Ukubekwa komkhiqizo kufanele kusatshalaliswe ngokulinganayo, ngaphandle kokufaka noma ukuncipha.

Qala ukutholwa

Cindezela inkinobho yokuqala emishini bese umtshina yensimbi uqala ukuthola umkhiqizo. Imiphumela yokuhlola izodonswa isikrini sokubonisa noma isinali ye-Sound kudivayisi.

Ukuhlukaniswa Nokucubungula

Ngokwemiphumela yokuhlolwa komtshina wensimbi, imikhiqizo equkethe le ndaba yakwamanye amazwe iyahlukaniswa futhi icutshungulwe. Ngemikhiqizo efanelekile, bangaqhubeka nokugeleza kulayini wokukhiqiza; Ngemikhiqizo engafaneleki, kufanele isuswe, futhi izimbangela kufanele zitholakale futhi zithuthukiswe.

Imishini yokuhlanza

Ngemuva kokusetshenziswa kwesikhathi eside, ipuleti lokutholwa kanye nenzwa umtshina wensimbi kungangcoliswa, kuthinta ukunemba kokutholwa. Ngakho-ke, imishini idinga ukuhlanzwa njalo. Indlela yokuhlanza inganqunywa ngokuya ngesimo sangempela, njengokusula indawo yezinzwa ngokotini wotshwala, noma ukusebenzisa i-vacuum cleaner ukuhlanza indawo yokutholwa kwepuleti.

Cisha imishini

Ngemuva kokuqeda umsebenzi wokutholwa, udinga ukucisha amandla womtshina wensimbi kuqala, bese unqamula ukuxhumana kwamandla. Ngasikhathi sinye, yenza umsebenzi omuhle wokulungisa imishini ukuqinisekisa ukusebenza okuhle kwemishini.

Ngamafuphi, ukusebenza komtshina wensimbi kudinga ukwenziwa ngokuya ngezinyathelo ezithile, kufaka phakathi ukulungiselela, ukulungiswa kwemishini yokuzwela, ukubekwa kwemikhiqizo, ukuqala kokutholwa, ukuhlukaniswa, ukuhlanza nokuvalwa kwemishini. Indlela efanele kuphela yokusebenza engaqinisekisa ukunemba kokutholwa kwemishini futhi yandisa impilo yensiza yemishini.